Indra is a skilful partner in the design and manufacturing of a broad range of valves and manifolds, with solutions intended for various industrial sectors.

Established more than 25 years ago, Indra at Magenta (Milan, Italy) has accomplished a course of specialization in the design of valves for the oil & gas sector. Activity that over the time, thanks to the attention paid to the more and more specific requirements expressed by the market, has allowed it to be in the forefront in the development and manufacturing of valves & manifolds for instruments, needle and ball type SBB & DBB valves, implemented according to high quality and safety standards. The company is mainly characterized by the realization of 100% made in Italy products: from engineering to manufacturing, using raw materials of prevalent Italian origin. «Today – underlines Renato Imbriani, Managing Director – the attentive selection of the base material for the product implementation has become a fundamental and determinant requisite for our customers’ final choice. Especially in critical fields like the oil&gas industry where we operate. Besides, due to the globalization and the presence on the markets of manufacturers coming from rising Countries, also the excellent quality of raw materials is deemed a “must”; the selection becomes then for us an essential starting point, because the good product performance depends on that». Further guarantee of the high quality of the materials selected by Indra is the use of an instrument that analyses their peculiarities: Pmi (Positive Material Identification), a non-destructive method of analysis of the chemical composition of incoming raw materials, analysis sometimes requested by the customer but always and anyway performed by the company’s quality control department. Experience and innovation, then, always tuned with the target of satisfying the most different needs, with customized solutions, too.

From the product to the complete “package”

The line of designed and developed products is then perfected also with completion materials and accessories, making the company the privileged and reliable partner of numerous realities for the supply of complete “packages” of various products, mutually complementary. «The solutions that we develop – adds Renato Imbriani – are mainly used in the chemical, petrochemical, oil & gas, off-shore platforms and energy industry, as well as in shipbuilding and highly reliable components in plants and machines featuring very high value and technological content». Certified Iso 9001, the company can then satisfy demanding technical and performance requisites, relying on a well organized structure at its Magenta headquarters, where it operates on a property surface of about 3,000 square metres. A unit provided with modern machinery for very precise and accurate machining, with testing phases of single products in the various production stages. They have recently bought also a new machining centre to enhance the productive capacity. “It is a very huge investment – states Renato Imbriani –deemed essential to manufacture a high-end product”. The certification factor plays then a fundamental role for the certified quality of products. The certifications attained according to the regulations in force in Countries of EEC and/or outside EEC area are provided as enclosures to Indra products (certificates “Fugitive emission”, “Ped”, “Atex”, “Fire Safe”, Api 598 etc.)

A bent for the constant development

Indra products are integrated into plants and machines of high value and technological content. Hence the need of paying particular attention to quality in all development phases.

«To be producers – points out Renato Imbriani, Managing Director of the company – allows selecting everything at best or, at least, in conformity with customers’ requirements: to manage delivery times, prices and quality of products».

Among the distinguishing qualities of the company, it is then worth mentioning also the great operational flexibility and versatility, necessary in those fields (like oil & gas) that require a continuous adaptation both in structural and material study terms. «It is then clear– further adds Renato Imbriani – that our production is not standard but on the contrary, very often, thanks to a consolidated bent for supplying the most suitable solutions for the various plant problems, oriented to manufacture valves according to the specific demands». Concerning this, the discussion between user and manufacturer is essential to permit the continuous development and adaptation to the reference sector, in compliance with new or in force regulations.

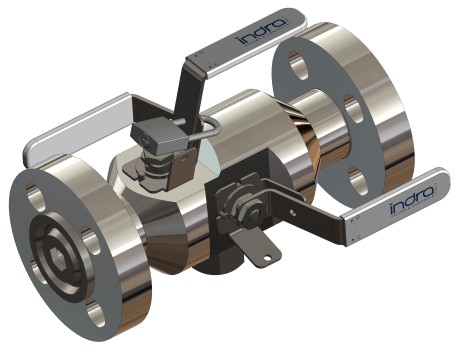

A single integral compact body

In the oil industry, safety holds fundamental importance and it is the requisite at the origin of the development of the Iblok valve line. We are speaking of a needle and ball-type valve line implemented to replace traditional “Christmas Tree” installation of multiple valves, combining in a single integral body intercepting (single “SB&B” or double “DB&B”) and vent/drain functions. Flexible and reliable, those valves, besides improving efficiency in process installations, offer relevant advantages of reduction of costs, installation and maintenance times, weighs, support and anchorage systems, leakage points and other problems connected with the presence of possible vibrations.

Available in various versions (with flanged, welded, flanged/threaded, flanged/flanged and single-flange extremities) and in various materials (from the more recurrent Aisi 316, A105 steels to special ones like Duplex, Superduplex, Monel, Inconel, Incoloy, Hastelloy-C etc.), the valves belonging to this series can also be equipped with accessories like lockout systems, electrical signals and so on, enhancing safety and efficiency requisites. Moreover, it is worth highlighting for Iblok valves the full compliance with the various reference regulations (Ansi/Asme, Api 598, Api 607, Ped, Nace std etc.), with specific product certifications (CU-TR for the Russian market, CRN for the Canadian market), in addition to the above mentioned ones.

The mentioned range includes also injection and sampling DB&B valves and is completed by a series of components and accessories for a correct installation.

Dear sir/madam,

This is Christina. Glad to introduce our company if you are interested.

Our company produce gate valve, globe valve, check valve, ball valve ,butterfly valve etc.

Our products have been exported to USA, Europe, Australia, Canada, Japan, Singapore, South Korea, middle-east and south- east Asia etc.

We produce ANSI/DIN/JIS valve with high quality and competitive price for 23 years in China.

We promise you a good quality , preferential price and fast delivery.

If you want to know more about us, pls do not hesitate to contact me. Look forward to cooperating with you.

Hey, Guys, I would also recommend Galassi & Ortolani here, they have been making special valves since years. The have a wide range of products, comprising: diaphragm valves, pinch valves, butterfly valves, ball valves, gate valves, check valves & pneumatic actuators. Here is their website: http://www.galassiortolani.com/category/butterfly-valves/

Gentile Andrea,

la ringraziamo per aver consultato e apprezzato i contenuti della nostra rivista digitale Power Transmission World.

Per promuovere l’offerta di GALASSI & ORTOLANI, La invitiamo a prendere in considerazione le proposta di comunicazione del nostro Gruppo Editoriale.

Un saluto cordiale

Anna Bonanomi

redazione

Thanks for sharing information related Manifolds Valve.