Gapi Group is pleased to introduce an Innovative Sealing Solution, the Anti-Rolling® Oring , designed by Gapi Group R&D, for High pressure application with reciprocating movements and for Axle Braking system.

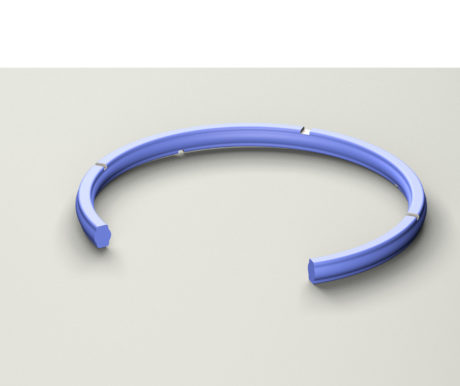

The Anti-Rolling® O-Ring is an innovative sealing solution designed to avoid one of the most popular and dangerous failure mode of the standard O-Rings: the spiral movement of the O-ring during assembling into the groove. Two lateral protrusions leaned to the central toric section, realize the Anti-Rolling effect. They totally prevent any twisting of the ring , both during installation and during exercise.

The lateral protrusions have another important role: they save the O-ring sealing surface from the damaging effects of the extrusion, without the usage of any addition anti-extrusion ring (back-up rings). No extrusion, under pressure, could occurs, where the protrusion play the role of back-up rings, in one-only solution. The presence of notches, positioned on both protrusions, prevents the bonding of O-Ring with the groove. They also realize ventil-effect in case of residual pressure.

Summarizing the benefits of the Innovative Anti-rolling® Oring, we can mention:

-It’s simple shape with later protrusion, prevent twisting effect during both assembling and during exercise;

-No lateral movement in groove under pressure, therefore no extrusion;

-Fully interchangeable with standard Or+ Back-Up rings;

-It replaces two components (Oring+ back-up ring) with a single component, gaining advantages in inventories management;

Anti-Rolling® O-Ring is available in a very wide range of polymers and grades, like TPUs, NBR, FKM, HNBR , each of them properly suggested in consideration of the specific operating conditions of the single application. For instance, TPU Anti-Rolling O rings successfully passed tests at 200 bar, 900 cycle/hour, for more than 400 hours. Other example is Rubber Anti-Rolling Oring which outperform test for more than 1.000.000 cycles , 90Bar @90°C