Vacuum-operated lifting cylinder picks up test pieces quickly and reliably

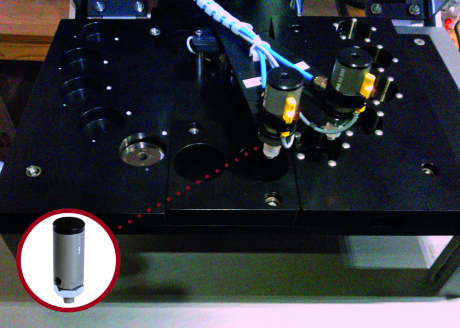

For STVision GmbH, FIPA has designed a customer-specific handling solution that takes coded discs out of a storage stack and brings them to a testing site. The handling solution is based on a vacuum-operated lifting cylinder that can stack and destack thin, fragile objects in short cycle times.

STVision GmbH is a company specialised in industrial automatic inspection systems for clients in metal, watch, automotive and semiconductor production as well as in the medical industry. A solution for an automated testing system for coded discs that could take the test pieces out of a storage stack and bring them to the testing site was being looked for.

Previous trials with vacuum cups had failed to provide satisfactory results since these were incapable of taking up the discs individually in a reliable fashion. The coded discs to be tested have a diameter of approx. 50 mm and are electroformed metal sheets with a nickel component, making them magnetic. However, the use of a magnetic gripper also proved impractical. Due to the high-performance permanent magnet, the magnetic gripper would take up several of the discs at once – an error which led to interruptions in the automated testing process.

The company contracted FIPA to develop a reliable handling solution because of their high level of expertise in vacuum and gripper technology. For the ideal procedure for the reliable uptake of a single coded disc, FIPA suggested a combination of a vacuum-operated lifting cylinder and a vacuum cup. With its anti-twist piston rod and robust, Hartcoat®-treated aluminium housing, FIPA’s lifting cylinder is optimised for the short-cycle-time stacking and destacking of thin work pieces. In application, the vacuum cup can pick up the upper-most disc so quickly that it is always correctly and reliably separated. The result is a very fast cycle time of less than 3 seconds. The testing system has now proved its value at a company in Colorado, USA.