Vuototecnica has selected Teseo’s manifolds to handle vacuum at their testing benches, where products are checked to identify the best solution for customer-specific applications.

The Italian company Teseo srl, specializing in the design, production and sale of aluminum piping and fittings for the construction of distribution plants for compressed air, vacuum, nitrogen and other fluids under pressure, supplied their modular manifolds to Vuototecnica, based in Beverate di Brivio (near Lecco, Italy), a manufacturer of vacuum components such as vacuum cups, vacuum pumps, vacuum generators and vacuum gauges.

Teseo’s HBS profile had already been adopted by Vuototecnica in the past, to build the vacuum buffer for their Octopus system, a solution designed to meet the ever increasing demand for operating flexibility of palletizing robots and vacuum grip systems in general.

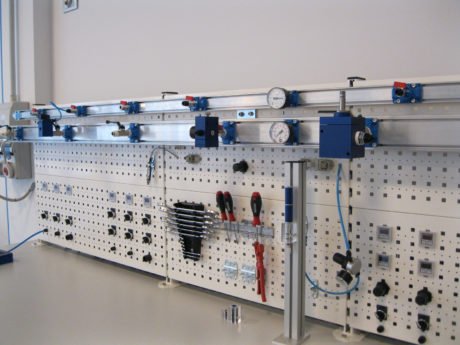

Now, Teseo has been selected again to provide the manifolds to handle vacuum at Vuototecnica’s own testing benches for two main purposes: train students and apprentices, and product tests to identify the best solution for customer-specific applications. «Internal tests are critical to prove the effectiveness of our products to customers, therefore we must have connections and vacuum cups always within reach», explains Adam Cogliati, Quality Manager, Vuototecnica.

For this implementation, Vuototecnica chose the HBS 32 and HBS 80 profiles. Teseo’s manifolds support the movements of vacuum cups for gripping tests, achieving vacuum values of -960 mbar (-96 kPa).

«We selected Teseo systems again because they stand out among other types of piping for a number of innovative features – said Adam Cogliati -. First of all, Teseo modular systems are convenient and versatile, enabling easy and quick line modifications; this is essential to adapt our test benches to ever-changing needs, adding connections as needed, for instance».

Teseo pipes do not require conventional threading or welding operations to be assembled. All parts are joined using special clamping brackets, locked by means of Allen screws. This innovative concept, combined with the square profile of the extruded aluminum bars, makes it easy and quick to assemble and modify any distribution system, using simple tools such as Allen screwdrivers. All accessories, such as outlet ports or drop columns, can be installed in few minutes, keeping the system under pressure.

«Another key factor for our decision was the high-tech look of Teseo piping, which conveys the image of an elegant, modern and functional product», Adam Cogliati ends.

About Vuototecnica

Thanks to its uniquely articulated know-how, maturated in over 35 years of activity side by side its customers and deriving from a great passion for vacuum passed on from father to son, today Vuototecnica, as its second generation, is leader in Europe in technologies for creating and handling vacuum.

Collaboration with other leading companies and its wide case history have led Vuototecnica to make the continuous improvement its guiding principle.

This is why concepts such as quality, tailor-made and versatility are considered as a big part of the company culture.

Vuototecnica with its problem-solving approach represents a firm point of reference for its customers, acting as a true engineering partner providing not only high quality products, but also a wide range of ideas and solutions to optimize production processes in many application fields.

With a comprehensive range of vacuum components like suction cups, vacuum pumps, vacuum generators, pneumatic pumpsets and a very talented team, Vuototecnica can deliver the best solution for your needs.

See a showcase of Vuototecnica vacuum technology applications: http://www.vuototecnica.net/video5.php

About Teseo

Teseo srl was founded in 1988 and immediately emerged as a pioneering, innovative and creative company. In the early ‘90s, Teseo was the first company worldwide to develop a modular system of aluminum profiles for the distribution of compressed air. Today, these systems have set a reference at international level for fluid power distribution such as compressed air and vacuum, both in small handicraft workshops and the big industry. The modular piping systems by Teseo are installed in the most different fields, with prestigious references in the automotive, textile, mechanical and automation industries. Besides the Italian headquarters in Desenzano del Garda, Teseo srl has five subsidiaries: Teseo Iberica, Teseo Nederland, Teseo UK, Teseo Deutschland and the first North American branch office, Teseo Canada.

Teseo’s distribution systems are manufactured in compliance with the safety requirements of the applicable standards and have obtained several product certifications. Besides manufacturing and selling its products, Teseo supports partners and customers for plant design and dimensioning, the study of tailored solutions for machinery and productionlines, consulting on standards, training of installers and engineers, supervision during installation and tests.

Design is a key factor in plant engineering, as it helps minimize waste and maximize performance. All too often, the development process of a traditional installation is divided into “tight compartments”, i.e. each stage is handled by actors that do not interact with each other. The resulting plant has no overall vision and incorporates several risks: high operating costs, leaks and high energy consumption, requiring expensive extraordinary maintenance to compensate. Teseo systems prevent all of this, as they are based on aluminum piping with highly reliable and resistant joints, and an overall project vision for an efficient plant that lasts over time.