Flexibility and operational efficiency, coupled with the quality of both standard and customized products, upon specific demand, make Demac a qualified and global partner for the development of solutions intended for the industrial handling in general and lifting: from machine tools to truck cranes, crane trucks and telescopic platforms.

Since 1981, Demac has produced the broadest range of hose reels and cable reels exported worldwide. Over 500 base models, 3,000 versions for each specific requirement; developed by its Magenta headquarters, in the outskirts of Milan, to satisfy each need through a business policy oriented to quality, reliability and research. Therefore, a reality that intends to represent not only a mere supplier but instead a partner, to face and to meet the market demands thanks to a diversified technical heritage, know-how and competences.

«Solutions – specifies Fabio Varano, Management of Demac – mainly intended for the industrial handling and lifting general, from the machine tool to the reseller, besides those managing hydraulic components. Historically, we are undoubtedly a reference partner in the OEM supply ambit in Italy and worldwide, in the sectors of truck cranes, crane trucks, telescopic platforms, lift trucks and telescopic handlers».

Production that today means for the company an export corresponding to 85%, steeply rising value in the last few years, considering also the difficult industrial context that has characterized (and that in a certain sense is still characterizing) our Country.

«The market requirements– adds Varano – have changed as well, increasingly oriented to the need of relying on more and more customized solutions. Fact, the latter, that has determined a change also of the internal production, precisely to satisfy these needs».

It is worth underlining that in the last decade the company has doubled its sizes, both in terms of engaged personnel (who today counts about fifty people), and in terms of productive spaces.

«A significant reorganization – adds Varano – that has led Demac to manage directly in its factories more than 80% of the machining needed by the various productions. Not only to improve further the intrinsic quality of the proposed ranges but also to grant higher flexibility and cost reduction».

Flexibility and efficiency that result in average delivery terms of standard products within 2 weeks, and of 4/6 weeks for executions implemented upon precise specification. Besides, to satisfy all kinds of needs, they have introduced a very fast delivery typology that allows customers to receive their products in 24, 72 or 120 hours.

Standard or customized, but high-quality

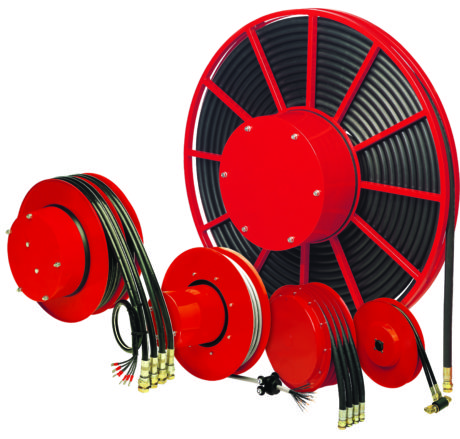

Broad and diversified, the production converges into a multitude of hose reel executions (up to 6 hydraulic ways, automatic, with hose locking or manual, combined electro-hydraulic, for low/medium and high-pressure water, air, compressed air, oil, diesel oil and grease and for welding gases), cable reels (industrial automatic, for removal and angle control, motor driven), besides rotary electro-hydraulic swivel joints, rotating electrical sockets, swivel joints, hose-stops and hose guides.

Among them, stands out also a new range of cable reels for Profinet cables, recently developed by the company.

«We increasingly aim – adds Varano – at succeeding in managing the customization of customers’ special requests».

In the last few years, Demac has invested huge resources also in other two product ranges, i.e. in the development of electrical rotary feeders and motor-driven cable reels. Product ranges already included in the catalogue for a long time but upgraded by a strong innovation towards the standardization, fruit of an intense research and development activity.

«Rotary feeders – underlines Varano himself– are dedicated to the industrial handling and can be used in several sectors, from earth handling machines to lifting, concrete pumps, hydraulic drills, machine tools and agricultural machines».

Motor-driven cable reels are instead available in 40 standard models, from 30 to 100 metres, but they can be customized according to precise specifications.

Inside DEMAC, the certification aspect holds fundamental importance, too. From this point of view, in addition to the ISO 9001 certification (quality management system in force for over twenty years now) and ISO 14001 concerning the environmental management system (attained in 2014), the company is in phase of OH SAS 18001 certification (Occupational Health and Safety Assessment Series, i.e. an international standard that fixes the requisites expected from a management system protecting Workers’ Safety and Health).

«A further decisive step – adds and ends Varano – that actually confirms the will of paying attention to the product, to the process and also to all the related activities and to the people entrusted with the execution of the various tasks».

Demac in brief

The Italian company Demac was established at the end of 1970 thanks to the entrepreneurial farsightedness of Domenico Varano, after a work experience and a professional career gained by a renowned manufacturer of lift trucks and telescopic handlers. In that ambit, he started then developing new technical solutions, the first steps at a new small productive site at Cisliano, in the outskirts of Milan, before moving to Cerello (MI). The positive results achieved on the market with the introduction of a broader and broader range of hose reels and cable reels for industrial and lifting applications, urged a new growth step. The owner in person decided a new move to Corbetta (MI) in 1995, in even better organized premises from the point of view of the productive process. As small local reality, Demac started widening its range of action, consolidating its position in a more and more competitive market. In 2005, Domenico Varano, supported in the company’s management by his sons Fabio and Laura, to serve better their customers, decided the transfer to the present headquarters at Magenta (MI), where a staff of around fifty people today fulfils over 30,000 reels per year, developed to satisfy all applicative requirements.

SEE ALSO THE VIDEO: http://www.demac.it/azienda/

Hello, I am interested in a 4-pipe tube with a length of 12 meters the one. Please tell me if you have the exact cost for shipping in Greece Thank you very much

Dear Mr. Tsapatoris Dimitrios,

we We are glad you appreciated the content of our magazine Power Transmission World.

For any request and information about DEMAC Hoses, you could directly contact Mr. FABIO VARANO by DEMAC to the following address:

f.varano@demac.it

Best regards

Anna Bonanomi

editor