Determination, competence and confidence are the instruments that have allowed Euro Group to become one of the leaders in the production of stators and rotors for electric motors and generators.

To know from close-up this fine industrial reality, we meet the President Mr Sergio Iori.

He welcomes us in his office at Baranzate, in the outskirts of Milan (Italy), where the cardboard template of a manor, hanging on an invisible nylon thread, reminds that it is typical of dreamers to build “castles in the air”. The determination, the competence and the confidence in one’s own resources are the instruments permitting to transform the boldest dreams into real and measurable outcomes.

The “castles in the air” that Sergio Iori has turned into sound reality must be many indeed, if in almost fifty years of activity the small company “Eurotranciatura” has given birth to Euro Group with its international sizes.

Can you give us some information about the history of Euro Group?

We started in 1967 with the company Eurotranciatura, established by three cousins. We had 6 workers and 2 presses; also today, the Group is family-owned and it has neither banks nor other institutions among its members. After almost fifty years of activity, Euro Group employs 1,400 people subdivided among the various factories all over the world and it has more than 115,000 covered square metres for its manufacturing activities.

In Italy, the following companies are part of Euro Group: Eurotranciatura, the parent company’s factory for the production of blanked laminations, Euroslot for magnetic blanked and punched laminations, Alcast for the die-casting of rotors, Corrada for progressive blanking dies, Euroslot Tools for compound blanking dies and SAF for blanked laminations and components for small electrical motors.

Globally, we are present with manufacturing units in Mexico (Eurotranciatura Mexico), in the USA (Eurotranciatura USA LLC), in China (Euro-Misi Lamination), in Tunisia (Eurotranciatura Tunisie), and we are in progress for the implementation of a new factory in Russia.

All divisions of Euro Group, established in Italy and abroad, produce blanked laminations and die-cast rotors. Two interesting numbers: 265 million Euros of consolidated turnover in 2014 and over 250,000 tons of steel strip processed, which constitute our raw material.

Stating this data, and the trend they express, are impressive but would be trivial. Tell us about your products.

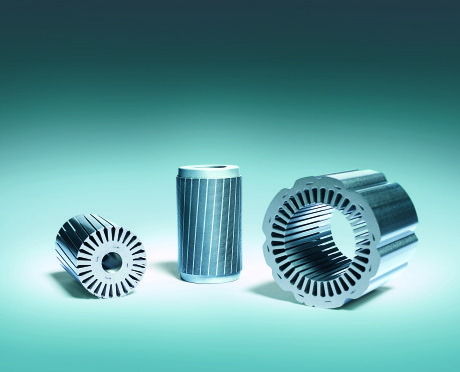

Euro Group supplies stators and rotors used in the main construction of rotary electrical machines, both electric motors and generators. For their manufacturing, we purchase and blank steel strips of electrical grade steels with variable thicknesses from 0,2mm to 1 mm. Such steels are often alloyed with a percentage of silicon.

Our blanking operations are carried out by progressive or compound dies that we produce in our subsidiaries Corrada and Euroslot Tools.

As an international Group, you have then customers worldwide …

Some years ago, I found in a daily paper a neologism that intrigued me: “Glocal”, that is to say being simultaneously Global and Local, relying on the capability of satisfying the global market without losing sight of our origins. We are an Italian company and we want to remain rooted in our Country: Italy. To facilitate the growth of this Italian Group, and upon our international customers’ demand, since 2006, we have set up production units abroad. A significant case for all: a big European company, our customer, had also a factory in Mexico and asked us to start producing in this Country. It was 2006, the starting year of our internationalization.

This vision, besides permitting to increase our sale volumes substantially diminishing costs for our customers, has also allowed “riding” the long wave of the various crisis situations that have followed one another in the last few years.

In 2013 we established a 50% joint-venture with the Japanese Marubeni – Itochu Steel for the realization of Euro-Misi Lamination, the afore mentioned production site in China.

Let us speak of your products’ quality.

We buy non-grain-oriented magnetic steel, we blank it and we supply it either loose or assembled, in stator and rotor packs. The assembly of stator packs can be executed by welding or interlocking.

Rotors are supplied in the form of loose laminations or die-cast assembled packs, using aluminium with 99.7% purity or its alloys.

We are potential suppliers for the manufacturers of all types of electric motors and generators. Our stators and rotors find applications in a countless series of sectors: automotive, industrial motors, household appliance motors, ventilation and conditioning, water pumps, traction motors and generators in their various applications.

Your products are also included in sectors needing high mechanical precision and higher electrical efficiency. How do you satisfy such demands?

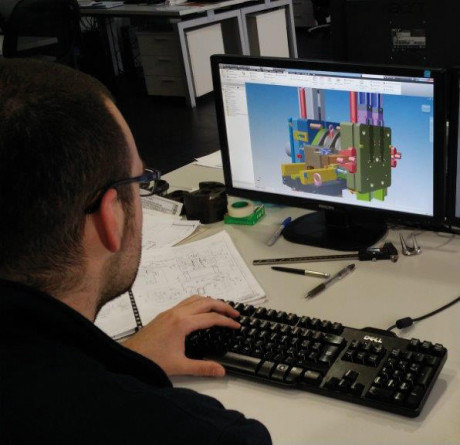

The quality demanded by the market requires precise project planning and innovation. Since the early phases. In Euro Group there is the operational unit Efficiency Team that offers customers both mechanical and electrical technical support in the design of the most efficient template of the blanked lamination that will be used.

At this stage, we start the design and construction of the blanking dies in our toolshops Corrada and Euroslot Tools; companies renowned on a world scale. The strict tolerances that we can attain on the blanked finished part will determine the efficiency quality of an electric motor. The use of steel strips supplied by the best steelworks on a world scale grant suitable typically electric values of stators and rotors, permeability and losses in iron for the good final quality that customers expect from their rotary electrical machine. The quality of the die-cast rotors manufactured by our Alcast foundry shares in the high efficiency of our products.

With the acquisition of a stake in the Japanese toolshop Kuroda, other primary sector player, Euro Group has gained and imported a new effective manufacturing technology called Glue Fastec: the assembly of the lamination pack is executed while blanking and performed with precision spot points of glue; this innovative system allows the creation of packs with improved mechanical and electric characteristics thus satisfying the market demand for increased efficiency..

What are your projects for the future?

New projects, ideas and concepts arrive daily so we are continuously evolving therefore our work is never completed!

Dear Sirs,

I have sent an inquiry to you days ago , as yet I have not received any reply!

Kindly, advise.

Regards

Monzavi

Dear Mr. Monzavi,

for further information about EURO GROUP, you can directly contact the Product Manager Mr. Marzio Andrea Iori, to the following address:

marzio.iori@eurotranciatura.it

Kind regards

Anna Bonanomi

editor

I have 25 years of experience in the field of Electric Motor Lamination machines.

Now, I have my own business venture here in Mumbai / India. In case you desire any business support, I shall be happy to provide the same.

(I have been the Ex- CEO of Schuler India)

Please advise your business interest.

Sehr geehrte Frau Bonanomi,

haben Sie schon Rotoren mit Kupfer?

Ich weiß, dass bei Ihnen schon lange gearbeitet ist.

Mit freundlichen Grüßen.

Andrey Koulov

Dear Mr. Kulov,

do you need to receive more information about rotors produced by Eurogroup?

Best regards

Anna Bonanomi

editor

Sehr geehrte Frau Bonanomi,

haben Sie schon Rotoren mit Kupfer?

Ich weiß dass bei Ihnen schon lange gearbeitet ist.

Mit freundlichen Grüßen.

Andrey Koulov

Can you advise who we must contact for unwound stator packs for induction motors in the range 1,5 to 132kw at 2pole 4 pole and 6 pole speeds.

Regrds

Chris

EPS PUMPS CAPE TOWN SOUTH AFRICA

Dear Chris Higgings,

for further information about Euro Group, you can directly contact Mrs. NICOLETTA IORI to the following address:

nicoletta.iori@euro-group.it

Kind regards

Anna Bonanomi

editor

Dear Chris,

you can contact Mrs. NICOLETTA IORI by Euro Group:

nicoletta.iori@euro-group.it

Kind regards

Anna Bonanomi

editor