Young and dynamic company, established in 2018, Eklego develops, designs and implements automation, vision and robotics systems with particular care of flexibility, efficiency and sustainability requisites. The expertise of its team members, who held responsibility roles in engineering and manufacturing ambit by multinationals of various sectors, allows putting at customers’ disposal structured analytical skills, able to create added value through a detailed process analysis and the consequent proposal of customized applications and solutions. Moreover, the commercial agreements with some strategic suppliers result in the proposal of unique unrepeatable solutions in many applications.

Increased productivity in the packaging and palletising of boxes

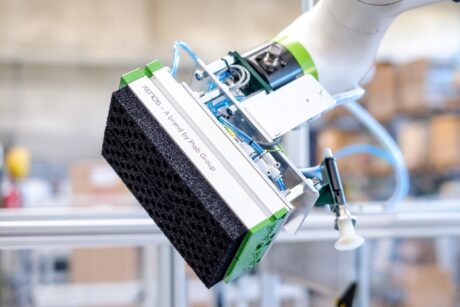

Specialized in packaging machines, robotic isles for the unloading of components-assemblies, robotic palletizing isles and automated pick-and-place plants, the company has also manufactured a forefront line-end for one of its customers, which allows managing different kinds of box according to process needs and requirements. Decisive to achieve the expected process performances were also grippers, that is to say the gripping systems of the Kenos series by Piab.

Reliable and safe handling

More in detail, Piab gripping systems of Kenos series installed in the line-end plant by Eklego are four in all: two KVG60, one KVG120 and one KVGL.

KVG gripping systems pick, from a conveyor belt, some cylindrical components/assemblies of various formats and with different surface finishes (paper, plastic and so on …) wrapped in a shrink film. Then, they are inserted inside cardboard boxes, automating a process that was previously managed manually. The automatic system operates KVG60 or KVG120 grippers, depending on whether a single package or two packages are picked, according to the customer’s specific order. Boxes are then closed and taped, with a production of two boxes per minute. Afterwards, the KVGL gripper picks the boxes and positions them on the line-end pallet. Boxes of various sizes and with variable weight up to 30 kg are handled, for 19 different handled formats overall.

«Before using Piab solutions – affirms Angelo Bertazzolo, technical manager and owner of Eklego – the problem was the absence of gripping reliability, in particular while handling boxes of heavier format, which must also execute a rotation by 180°. Through the solutions adopted, we have succeeded in increasing the production by 30%. We have also tried another supplier of technical sponge grippers, but performances did not grant the same safety. Concerning the price, Piab product is slightly more expensive, but the advantage in terms of performances, development assistance and technical support compensates the investment extra-cost. We are so satisfied with the solutions adopted and response times by the technicians of Piab and Europair, Piab authorized distributor, that we will go on collaborating with them also in future projects».

Versatile grippers, in two sizes with high configurability

Vacuum Kenos gripping systems by Piab are developed to simplify handling processes in various industrial sectors and many applicative ambits. It is a versatile range, based on grippers made of technical sponge or with suction caps, studied for the handling of a broad variety of objects with different shapes, sizes and materials. Such gripping systems can be equipped with integrated vacuum generation through COAX multi-stage ejectors, still by Piab, like in the case of the grippers installed by Eklego, or prearranged for the external vacuum generation, for instance by means of blowing electrical pump with side channels.

Kenos KVG series is available in two width sizes, KVG60 and KVG120. They are fully configurable grippers in terms of length, type of sponge perforation or suction caps, typology of internal technology (with shut-off valves or with calibrated hole) or of vacuum generator, and they allow handling several object typologies in manifold industrial sectors, from the furniture industry to packaging.

Minor quantity of necessary compressed air, more efficiency

Mainly designed for the handling of boxes, Piab gripping systems series Kenos KVGL chosen by Eklego show a sponge assembling system that allows a fast replacement in case of wear, without needing the intervention of specialized maintenance technicians or the use of tools, so enhancing the plant’s productivity. The already mentioned COAX vacuum-generation technology minimizes the energy consumption, meanwhile providing a safe fast gripping, due to its high initial flow rate. The pump unit can provide high performances even with low or fluctuating supply pressure. This has been demonstrated in independent comparative tests carried out by “Fraunhofer Institute for Machine Tools and Forming Technology IWU” in Dresden. These tests have demonstrated that Piab ejectors need a much lower quantity of compressed air to obtain the same result as ejectors by other suppliers. Consequently, their use decreases the compressed air supply cost and then the total manufacturing cost.