Both for mechanical seals and for bushing of low power asynchronous and brushless water pumps, Meccanotecnica Umbra provides solutions able to avoid noise and reduce friction an losses.

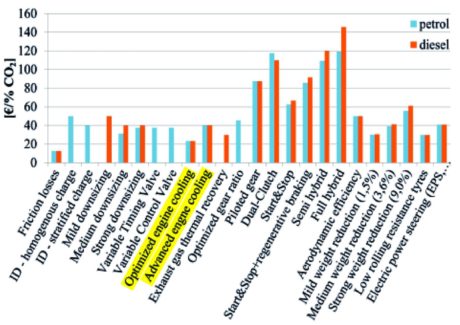

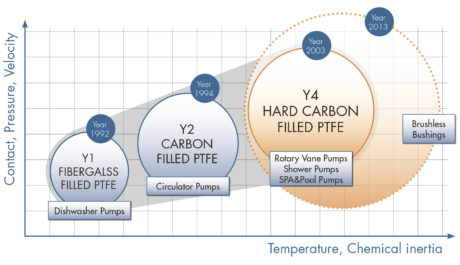

During the last ten years, the market has requested sometimes to increase the operational flexibility of cooling systems using auxiliary pumps for a better control of engine cooling and efficiency, in order to meet more stringent regulations in terms of CO2 emissions. In many cases the auxiliary pumps are driven by brushless motor, regretfully still with some limited performances in terms of pump efficiency and vibrations/noise failures, as it has been for dishwasher application of this type of motor. Meccanotecnica Umbra developed a material for sliding parts such as bushings to reduce the sliding friction: the solution had been the MTU Ptfe material with appropriate fillers, Mecflon.

Meflon, when compared to other grades of Ptfe, is formulated to provide increased efficiency, improved wear resistance, and decreased starting torque in demanding applications of food, spa, and drinkable water segments. As it was for the mechanical seal of dishwasher pumps, MTU analyzed the possibility of supplying in particular bushings and rings, made with same innovative materials to prevent sticking and noise, to Tier1s and OEs that are partially replacing the traditional pumps (equipped with mechanical seals).

The irregularities of performances in real conditions are related to the occurrence of irregular flow situations and for mechanical seal, this phenomenon is bigger, because the lubricating film between the faces is typically very small. Therefore, the effect of Mecflon also for bushings has been again the key factor for avoiding sticking and noise, as it had been for traditional low power electric pumps, provided with mechanical seals.

In the past two years MTU has got relevant progress in the definition of the project for brushless motors and has overtaken the preliminary testing activity on prototypes, with sizeable advantage also in terms of wear, and not only sticking and noise, in comparison with standard materials used for mass production. Pumps equipped with Ptfe bushings don’t present axial wear of the front flange of the bushing and show lower wear of radial surface. However, the combined radial wear of bushings and shaft for Mecflon Y4 solutions makes significantly lower overall damage in terms of eccentricity. Morerecently MTU has started a specific development program for application of PTFE bushing to cooling system water pump , taking into account the typical working conditions of the automotive segment (-40/140 ° C, up to 6000 rpm, high additivated coolant, continuous operation during in-house recharge of batteries of hybrid or electric vehicles).