The Italian company Kratospack developed a new generation of Power Units.

Kratospack catalogue includes an innovative range of Power Units with low energy impact that can satisfy several requirements in the industrial automation market.

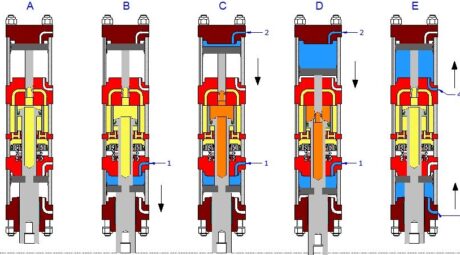

The Power Units is the synthesis of two applied technologies: the pneumatic motion, fast and cheap used for the approach and the return from the working area and the hydraulic power increase, obtained by a mixed multiplication system of compressed air – hydraulic oil, whilst the strict and indispensable separation of the two fluids is guaranteed.

The range offered at present by Kratospack is in the bores 50, 63, 80, 100 and 125 mm; it is in program in the near future the extension also to the bores 160 and 200 mm.

Available in two versions

For all the above-mentioned bores two versions are available:

- the HLU version in which the hydraulic multiplier is assembled in line with the pneumatic actuator;

- the HPU version in which the hydraulic multiplier is assembled in parallel with the pneumatic actuator, suitable to be used in more reduced spaces.

Regarding the forces available, they go, with operating pressure at 6 bar, from 8.5 kN for the bore 50 mm to 115 kN for the bore 125 mm, with the possibility to increase forces between 25% and 30% in the version “X”.

Application advantages

The main advantages of such Power Units are the fast approach and return from the working area that allow fast cycles with a consequent increase of the productivity and the maximum cleanliness of the working area for a possible use in fields like automotive, household appliances, aviation, assembling of complete lines and so on.

Furthermore, their peculiarity is the modern and clean design of the actuator that allows the mounting of position transducers in the grooves of the profile.

At last, their high strength obtained by using caps in steel and the optimization of the features.

Excellence of Made in Italy technology

These products are the excellence of a technology Made in Italy and their quality is guaranteed by the attention to component materials and to their machining.

All finished products are 100% electronically tested with the relevant recording of the data and the possibility to filling the specific features.

The Power Units proposed by Kratospack are successfully used in the industrial automation for blocking, assembling, cutting, flanging, drawing, banding, pressing, rivetting, clinching, stamping, marking. cutting, punching and in general in operation in which fast actioning speed and high working forces are required.