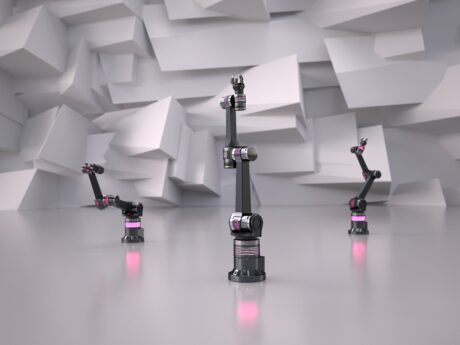

Smart System IHD: a smart, compact and highly integrated servo actuator

To be able to meet the requisites of several industrial and applicative sectors, Harmonic Drive offers both zero-backlash harmonic gearboxes and low-backlash planetary gearboxes, as well as servo-actuators based on these two types of gearboxes. A broad diversified range, further enriched by the introduction into the market of Smart System IHD, a new compact, integrated and smart servo actuator. We are speaking of a solution consisting of: a zero-backlash gearbox, a brushless servo-motor of new concept, a double feedback system, of which one measures the position of the motor shaft and the other the absolute one of the slow shaft and finally a powerful drive on board.

Double processor at the service of the condition monitoring

This new servo-actuator can be equipped with smart on-board sensors that can be opportunely prearranged, for instance, to provide objective information and assessments concerning the state of the gearbox or to highlight the eventual presence of vibrations, granting their continuous monitoring. This allows carrying out some predictive diagnoses, with the possibility of prearranging programmed machine idle times.

Concerning this, in fact, even if it is very compact, Smart System IHD is equipped with double processor, (one of which can be dedicated to applicative functions for smart condition monitoring functionalities), instead of being used as separate platform for specific applications.

User-friendly integration and fast commissioning

Other interesting peculiarities of Smart System IHD servo-actuators are the hollow central shaft, which permits the passage of a broad variety of electric and/or mechanical transmissions, and the availability of a software solution, purposely developed and user friendly, for a fast commissioning. All this is also joined by the possible power supply of the system with DC voltage at 24 V, at 48 V, typical of mobile applications with battery power supply.

High system rigidity

The new Smart System IHD servo-actuators stand out for being equipped with a double encoder: one for the piloting of the servo-motor whereas the other (absolute with single revolution) for the feedback of the angular position at the gearbox output.

Due to the position control on the output, the system can directly compensate possible angle variations caused by the load influence. The result is a much higher system stiffness than in the case of the standard control of the position loop through the encoder on the motor.

The stiff output bearing with crossed rollers can withstand high radial and axial loads as well as high tilting torques, so assuring a long service life and high performances. Therefore, in the vast majority of applications it is not necessary to provide for an additional load support bearing, with a consequent reduction of spaces and costs.

Performances and applicative potential in constant widening

The new servo-actuators by Harmonic Drive, whose communication with the master control occurs by means of CANopen, Ethernet or EtherCAT protocols, are currently available in three sizes, with IP68 protection degree. The range is anyway in constant development and, besides the introduction of suitable devices for the “condition monitoring”, a range extension is foreseen. An enlargement that will grant an even broader applicative potential.