Face to face with Giovanni Chinaglia, CEO of miniToolsCoating, a young Italian company, which conquers national and international markets with high-quality products and services.

The company miniToolsCoating, headquartered in Padua, was established upon the initiative of a renowned Padua entrepreneur, Mr Vincenzo de Stefani, and it is structured to operate in three branches that mainly concern the gear industry but also other engineering sectors. First of all, it offers a coating and resharpening service on all types of specific gear cutting tools for every type of gears. Hobs with a maximum diameter of 300 mm, lengths up to 350 mm and modules around 26 mm can be ground and coated. They are then big-size hobs that lots of users cannot resharpen because high-cost grinding machines would be necessary. Naturally, it is possible to grind smaller-size hobs with higher technical difficulties, like for instance hobs for worm gears with helix angle.

Concerning shaper cutters, both with straight and helical teeth, they reach diameters up to 250 mm and obviously there are no problems to grind also shank cutters for internal gears. The offer range is completed by the grinding of solid mill cutters for bevel gears with straight and helical teeth, with the additional possibility of grinding blades for cutters for spiral bevel gears. The service centre integrates its activity with the coatings of tools, moulds, dies and other mechanical parts, using the most cutting-edge plants and advanced technologies.

Besides, miniToolsCoating manufactures solid cutters for bevel gears. This type of tool is not produced by lots of companies; on the contrary, we daresay that in Europe Gleason has a monopoly. Therefore, it is a sector that potentially opens vast horizons.

We asked Mr. Giovanni Chinaglia (CEO) for detailed information about miniToolsCoating activity on the market.

What is the most important activity for the company?

The activity of miniToolsCoating is subdivided into three sectors:

Resharpening and coating service of gear cutting tools, corresponding to about 50% of the turnover;

Coating of tools, dies and mechanical components, with about 30% of the turnover

Manufacturing of tools, that’s to say solid cutters for bevel gears, amounting to 20% of the turnover.

miniToolsCoating was born as service company, but having gained outstanding know how in the sector of bevel gear cutting, it could start a high-quality production that is currently very appreciated by the market

This differentiation of the corporate production activity has permitted us to navigate without excessive damages in the economic crisis that grips the Country.

What are the salient characteristics that make miniToolsCoating tools interesting?

First of all customers appreciate the absolute precision of tools. Utmost care is paid to all the details of each single piece, with testing stations in each production phase.

Each piece is delivered with enclosed testing certificate that reports, besides each theoretical value, the one actually obtained. This certification grants the quality and reliability of tools to users.

The second qualifying point is the steel choice and the treatment care. The standard steel is ASP23, powder steel with high hardness and excellent toughness, ideal for cutters with which you essentially work in interrupted cutting operations.

But it is also possible to choose S390, super-alloyed powder steel, suitable for higher performances. Each batch of steel, before being launched into production, is controlled to verify that its characteristics are the expected ones.

Finally, the delivery of tools occurs in sturdy, elegant and customized wood boxes, which protect tools completely and allow a simple and comfortable storing.

Are there innovations in coatings, at the moment?

Yes, there are new specialized available layers that enhance the efficiency of the components for which they are intended. That mainly involving gear tools, that’s to say hobs and shaper cutters, is called ALTICROME. It is a multilayer with chromium, aluminium and titanium nitrides that reaches very high hardness, with operating temperatures that can reach even 1100 °C. It is then a coating suitable for tools that work under particularly heavy cutting conditions, with big heat generation.

Another new coating, conceived for carbide tools is called SILICUT. The coating with nanocomposite structure is obtained by incorporation of titanium and aluminium nanocrystals into a matrix of silicon nitride. This acts as strong interface and gives the typical structure of composite materials to the layer obtained.

We can guess, from the documentation delivered to us, that there are further specialized coatings, mainly applicable on moulds and dies.

It is worth mentioning for instance CROMVIC where, on a basis of chromium nitride, is deposited a carbon layer with amorphous structure, a middle way between graphite and diamond. It is a DLC (Diamond Like Carbon) type coating boasting very interesting features.

The film that coats the substrate can have thicknesses reaching 1 – 2 micrometres and couples high hardness with very low friction coefficient, just 0.1 – 0.2 that’s to say much lower than all coatings used in the tooling sector; it is particularly suitable for moulds.

This coating is made at very low temperatures, about 250 °C and this facilitates the coating of parts in constructions steel, which at higher temperatures might be subjected to distortions and to structural modifications, too.

The company is developing new coating types by using innovative plants and technologies in the forefront. The new coatings under study are conceived for HSS hobs with the target of improving the efficiency and with evident positive repercussions on production costs.

FinalIy, I am proud of underlining that, due to their long experience in the “service”, the company is very attentive to respect delivery terms. The standard is a delivery in 4 – 6 weeks, but what matters more is that, once fixed this term, they exhaustively comply with it.

Standard sizes of the cutters

Table 1 shows the standard sizes of the cutters currently produced, specifying that also cutters with different sizes can be manufactured. Crown solid cutter are solid cutters with big-size diameter that, for the assembly on the machine, need a mounting flange, that’s to say an adapter between tool and machine spindle. This adapter unavoidably causes a slight misalignment of the cutting edges with regard to the theoretical axis, generally included in 5 – 10 micrometres. But this is a tolerable inconvenience because in general the pieces produced with this type of cutters are ground afterwards. On the other hand, you can achieve notable savings compared to inserted-blade milling cutters. One of the feathers in the cap of this company is certainly the available technology for coatings. As already said, miniToolsCoating offers the possibility of coating any type of tool and a multiplicity of mechanical parts with a dimensional limit of 600 mm maximum diameter, 800 mm maximum length and maximum weight of 500 kg; in particular the possibilities can be summarized as follows:

The whole range of tools for gear cutting;

- Tools for general mechanics;

- Tools for high performances;

- Dies and components for blanking and forming;

- Moulds;

- Dies for die-casting;

- Punches and dies for sintering;

- Mechanical components.

| Table 1 – Standard sizes of cutters | |||

| Type of cutter | Nominal diameter | N° of teeth | Steel |

|

Solid cutter |

1.1” |

8 |

ASP23 Or upon demand S390 |

|

1.5” |

12 |

||

|

2” |

16 |

||

|

2.5” |

16 |

||

|

2.75” |

20 |

||

|

3.5” |

20 |

||

|

4.5” |

20 (standard) 24 (special) |

||

|

5” |

|||

|

6” |

|||

|

Crown solid cutter |

6” |

24 (28 – 30 special) |

|

|

7.5” |

32 (36 special) |

||

|

9” |

40 |

||

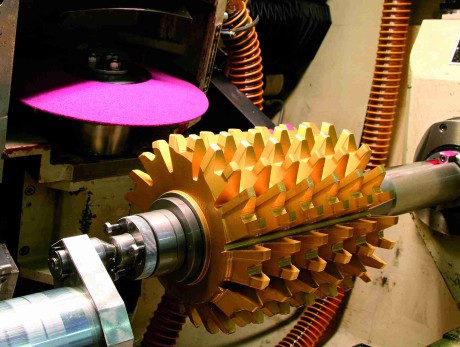

FigC

Profile grinding phase of a solid cutter for bevel gears.

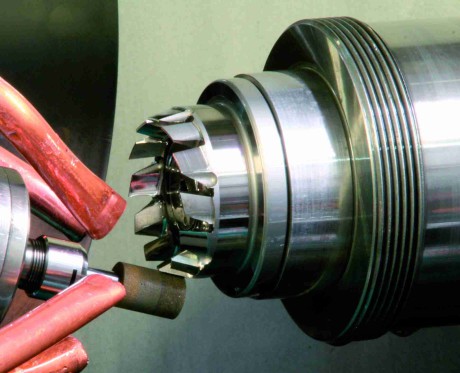

FigD

Micrograph of a multilayer coating. 1) Very hard and compact nanolayer. 2) Layer of TiAlN. 3) Substrate.

Hi

I’m calling from iran. we are using gleason type cutters and blades for machining spiral bevel gear.

we almost use russian made cutters. my company is also seles these cutters to factories in iran. if you can please send us your cataloge and price list for these cutter heads and blades.and also i have few question about symbols on russian blades.

we also use revacycle cutter blades and if you could help let me know.

Best regards

milad mohammadi

CEO: Tabriz Gear Industry

miladmohamady@yahoo.com

Tgearindustry@yahoo.com

Dear Mr. Mohammadi,

I thank you for appreciating the content of Power Transmission World.

For any request information about MiniTools Coating, you can direct contact Mr. Giovanni Chinaglia:

g.chinaglia@minitoolscoating.com

Best regards