New AX piston pumps and motors by Bucher Hydraulkics overcome limitations of present-day hydraulic units.

Piston pumps and motors have been established in the market for many years, and they are one of the main components, arguably the most important component, in a hydraulic circuit.

The technology behind a conventional piston pump is both simple and complex at the same time: pistons, usually 7 or 9 in number, convert mechanical torque into oil pressure. In a piston motor, the process is reversed. That is the basis of piston-based hydraulic drive units, and everyone who works with high-power industrial and mobile applications will be very familiar not only with their positive aspects but with the negative ones as well.

Limitations of current hydraulic units

Every project engineer has, without doubt, experienced the limitations of piston pumps or motors: high pressure ripple and not optimal mechanical as well as volumetric efficiency in all operating points.

In addition, the growing demand for electrically powered machines has also highlighted some inadequate performance characteristics such as noise and minimal shaft speeds when working at high pressure.

Industrial applications with ever-faster working cycles and high working pressures, together with a need for very responsive dynamics and accurate flow and pressure control, have already identified the limitations of current pump technology, limitations that are normally compensated for by using accumulators and valves, with the associated high energy wastage and costs.

New AX piston pump based on a new pump principle

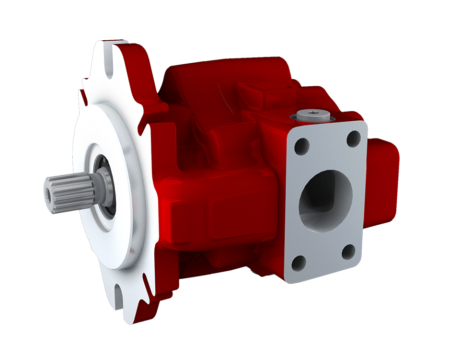

For these reasons, Bucher Hydraulics decided to improve and productionize a new pump concept that overcomes of the limitations of current piston technology, bringing to market not just a further evolution of the existing concept, but a real revolution in terms of better efficiency, excellent dynamics, low noise, and low minimum speed at high output torque.

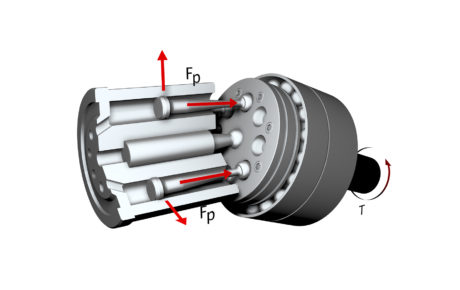

The Bucher Hydraulics piston pump is based on a new concept, which works on the principle of balancing the internal forces by having 2 rotating barrel plates, facing each other and each having 12 pistons, thus achieving a very high power density and limiting the axial forces, which need only a light bearing to absorb them.

After several successful years of research and development testing, Bucher Hydraulics is now proud to introduce to the market the new AX piston pump and AXM piston motor in displacements of 18 to 76 cc/rev, with an immediate target of extending the range up to 115 cc/rev.

APPLICATION EXAMPLES

Electrically powered construction machines

The characteristics of the Bucher Hydraulics AX pump have been studied with a particular focus on machines powered by an electric motor. The high volumetric and mechanical efficiency, low noise, low pressure ripple, and minimum permissible speed of 2-3 rpm, together with the possibility of enabling the pump to turn in both directions, make the AX pump the perfect solution for the electrical and hybrid machines of the future.

Winches

In the standard version, the AX pumps and motors can reach a working pressure of 450 bar.

This characteristic is not the main advantage, however. In the low-speed range of just a few rpm, the AX motor has an start efficiency of 99% against the 60-65% of a conventional axial-piston unit.

Thanks to this feature, the performance can be significantly increased, with the benefit of very slow and accurate crane movements. This characteristic benefits crane slew drives as well.

Industry

The performance of the new Bucher AX hydraulic pumps and motors means higher energy efficiency. This high performance is also evident when the unit must start rotating and run very slowly under high load and pressure.

Wheel motor

The high power density, high working pressure and low permissible speed make the AXM motor the perfect alternative to applying as gear motor. The minimum speed of 2 rpm at high pressure brings mobile machines into a new arena: new calculations are now possible during the study phase, with the big advantage of being able to choose different and higher gear ratios. For straight travel in vehicles such as crawler excavators, the volumetric efficiency of around 96% can really help to increase the speed with same motor size.

For further information about Bucher Hydraulics new AX pump and motors: www.bucherhydraulics.com/AX