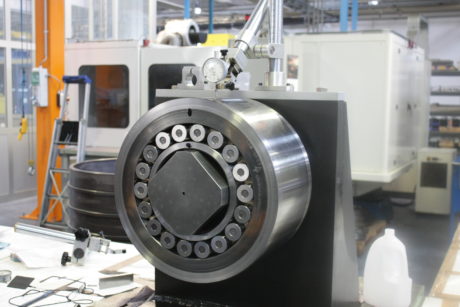

Iron and steel industry, railway, paper processing industry and machines for production of corrugated carton, tubular rope-making machines and wire processing, handling. They are just some of the main sectors where operates Faro, specialized in the manufacturing of cylindrical-roller axial and radial bearings, tapered and ball bearings, besides slewing bearings, from a minimum hole of 20 mm up to 6,000 mm of external diameter. In recent years, Piacenza company has in fact invested huge resources in both the manufacturing division and in the quality control department, to approach as qualified partner a wider and wider array of operational fields, wherever big-size bearings are requested.

«As in the case of large machine tool industry – the owner and managing director Marino Bertoli explains – for which, for some years now, we have been designing and manufacturing with very positive outcomes axial and radial bearings for rotary tables, with or without cage, to be supplied in ISO P5 or higher precision class».

We are speaking of bearings that, due to the ambit where they are used, must satisfy very severe technical specifications in terms of rigidity under load, besides assuring speed, precision and high reliability.

«Executions – Bertoli adds – for which we can supply also a certificate of the friction torque, very appreciated by manufacturers, which highlights our precise will of standing out from the market by providing our products with further added value».

In particular, the test bench, which allows Faro to measure and to certify the pickup torque of bearings, can carry out up to 5,000 readings per second. The system permits to choose the starting torque value, the maximum one, the increment and decrement rate. The data registered by the load cell during the entire control cycle can be visualized in a graphic report and then enclosed, as certification, for each single bearing.

Co-design and co-engineering at customers’ side

Flexible, dynamic and highly qualified, Faro can work at customers’ side with co-design and co-engineering activities, acting as problem solver and sometimes developing unconventional solutions, too.

«In other words – Bertoli adds – our mission is providing our customers with the solution to those criticalities and technical problems that hardly find an answer among the products generally at disposal on the market».

Like for instance the case of the quite frequent applications for which the available overall dimensions for the installation of the bearing cannot be modified. However, at the same time, some determinate performance requisites are needed (load capacity, speed, duration and so on).

«In this case – Bertoli underlines – according to specific requirements, we can satisfy the expected requisites by intervening on materials, turning to suitable heat treatments as well, to the study of new geometries or to particular lubrication systems, too. We have recently implemented, for instance, for the oil&gas industry, an alternative bearing to the standard one available on trade whose duration, however, was not deemed satisfactory. After attentive studies, our technical office has proposed a specific execution implemented by modifying inner components and using different materials but keeping performances unchanged. A technological pair that has allowed reaching fully the duration targets demanded by the customer».

As already pointed out, the iron and steel industry represents instead one of the main historical application sectors to which the company supplies special bearings for applications on cold rolling mills, hot rolling mills and flattening machines. They are executions with multiple crowns of cylindrical rolls, i.e. multi-roll, to be mainly used on rolling mill cylinder necks or axial single-acting and multi-stage bearings or, moreover, spiders’ shells.

«In particular – Bertoli explains – in Sendzimir cold rolling mills are mounted some special support bearings, named counter-rolls, needed to push and to keep rolls rectilinear. We are referring to an application whose required dimensional precision is in the order of microns, as well as the geometrical one because the eventual eccentricity might negatively affect the process, damaging the final product quality».

In this ambit the company, besides supplying new bearings (with multiple rows of cylindrical rollers, with very thick outer rings and different structural shapes to meet whatever requirement), can provide an accurate revamping service, too.

«In this case – Bertoli specifies – we can carry out an in-depth damage analysis on the mechanical component and assess its repair costs. Besides dismounting and cleaning worn-out bearings, we can grind the outer coating of the external ring, replace eventual inner damaged and/or worn components and restore the section height through selecting».

So overhauled bearings assure the same performances as those achievable with new executions but they allow a significant saving to customers.

Certified quality

In almost 40 years of activity, Faro has gained specific experience in various industrial sectors, so acquiring all-round technological expertise and skills needed for the design and manufacturing of advanced engineering products. Made-in-Italy excellence that gives birth to an absolute-quality high-precision product, both standard and customized, which can be supplied in small batches, too. Activity carried out at Calendasco headquarters (Piacenza, Italy), with the support of a growing staff, who today reaches about fifty workers, and of a forefront diversified machine fleet.

«Manufacturing expertise – Bertoli highlights – that benefits also from a well-structured organization according to Lean Production and 5S methodology principles. Approach that allows us to coordinate and to manage each single job order at best, in very short times, to guarantee the highest competitiveness level».

Utmost attention to the process that includes the accurate choice of selected materials and components, provided with origin and guarantee certificates, in addition to the meticulous quality, in-process and metrology laboratory control. Worth highlighting at Faro’s the material control and testing office is organized in two units. The Material Control division takes care of carrying out metallurgical assessments of the raw material and of single component through: destructive tests with execution of micrographs, macrographs and control of the material’s chemical composition; non-destructive tests by means of ultrasounds, penetrating liquids, hardness micro-detections and magnetoscopic controls. The Testing division, in compliance with the procedures illustrated in the Quality Manual, performs instead dimensional and geometrical tests during all phases of the manufacturing cycle.

«To guarantee controls in the order of microns – Bertoli specifies – we avail ourselves of over 1,200 measuring tools and equipment, constantly calibrated with the aid of a certified calibration bench».

Since 2004 already provided with environmental management system according to ISO 14000, then upgraded to 2015, in 2017 Faro achieved the ISO 9001:2015 certification, too.

With a 2018-turnover that exceeded 10 million Euros, steeply rising versus the previous year, Faro looks at the future with the awareness of playing a protagonist role in the power transmission world, in national and international ambit.

«Our production – Bertoli ends – currently addresses markets beyond the borders by about 50%, mainly Germany, but we are developing interesting job orders also in Russia, in Turkey and in Australia. The domestic market is as interesting for us as, from our observatory, it seems it is living a very positive period. Even if we do not forget most of our Italian customers export their products».

Currently, at Calendasco headquarters (Piacenza, Italy), Faro Industriale can manufacture precision bearings from a minimum hole of 20 mm up to 6,000 mm of outer diameter.

Bearings with integrated gears

Constantly oriented to innovation, Faro stands out on the market for its great capability of representing a qualified partner for the manufacturing of special tailor-made bearings, aimed at solving determinate criticalities. Among the numerous designs developed by Piacenza company, stands out the one concerning a particular supply for epicyclical reduction gears, installed on machines intended for olive pressing. In this particular application, owing to work overloads, the efficiency of reduction gears was affected by an overload, with consequent phenomena of bearings’ capacity. Therefore, the customer asked for a review aimed at the achievement of the highest possible increment of bearings’ loading capacities.

After examining the worn specimens, carrying out an in-depth metallurgical study of the toothed wheel and considering the improvement of the lubricant type, Piacenza company’s staff implemented a new proposal. In other words, a bearing with the same sizes but characterized by some interesting technical peculiarities: the elimination of the outer ring, the toothed wheel function performed by the external ring, increased size of rollers. The targeted design has led to an optimization of the bearing’s inner space to attain a more efficient lubrication, an optimization of the global geometry and, especially, an enhancement of loading capacities (by a value exceeding 40% in dynamic phase and by 30% in static phase).