Half century of presence in the sector of brakes and clutches is a precious experience at the service of power transmissions. Today that know-how allows the Italian company M.W.M. Freni Frizioni to achieve outstanding results, both in standard applications and in those characterized by particular requirements.

Half century of presence in the sector of brakes and clutches is a precious experience at the service of power transmissions. Today that know-how allows the Italian company M.W.M. Freni Frizioni to achieve outstanding results, both in standard applications and in those characterized by particular requirements.

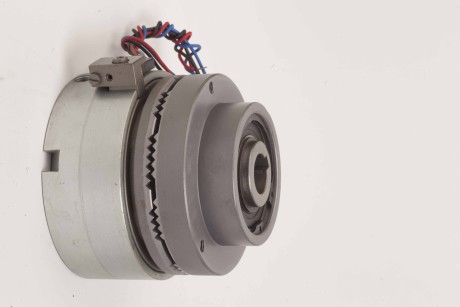

The industry of brakes, friction clutches, toothed clutches, torque limiting couplings and one-piece assemblies, with electromagnetic, pneumatic, hydraulic and mechanical control, and whatever else, seems to have reached its optimal technological level. Only apparently, however, because for M.W.M. Freni Frizioni srl each product represents the synthesis of great experience and the contribution of the most advanced design, production and control technologies.

This Italian company, established fifty years ago upon the initiative of Mr Carlo Witzel to produce mechanical multi disc clutches – at that time very used in industrial machines – still today makes innovation its war horse; smart innovation, in small steps, which allows MWM to obtain products with excellent performances while maintaining very small overall dimensions.

Still thanks to the constant innovation, the decrease of the mass-production, which occurred starting from the Eighties, has been abundantly compensated by the implementation of customized products.

«Today the market calls for tailor-made solutions, special products not included in our catalogue; – underlines Sergio Sartori, CEO of M.W.M. Freni Frizioni srl. – Our workshop at Samarate, in Varese province, is equipped to satisfy the most complex requests submitted by customers, all obviously inspired to our three catalogues, which include hydraulic, pneumatic and electromagnetic components, pneumatic and hydraulic calipers. We hold several patents, we are innovative, always researching ameliorative solutions; sometimes the market welcomes them positively, sometimes less due to a cost matter. The Samarate factory is equipped with all types of machine tools, from CNC lathes to machining centres, grinding machines, gear-cutting machines, slotting machines and so on. We have everything to make our activity independent».

Concerning innovation, M.W.M. Freni Frizioni presents the new range of caliper brakes, fully innovative compared to the previous one, with various patented technical solutions.

The line of MWM caliper brakes exploits six different intervention modalities:

- manual – with new design of the handle wheel;

- caliper brakes pneumatically applied spring released – for operation;

- Caliper brakes spring applied pneumatically released – for safety;

- DUO caliper brakes – for operation and safety;

- Caliper brakes hydraulically applied spring released – for operation;

- Caliper brakes spring applied hydraulically released –for safety.

Each of these solutions provides a broad choice in terms of braking torque, overall dimensions, assembling modality and brake disc thickness.

With the revolutionary self-aligning system with orthogonal sliding, the two lever arms are hinged on two steel pads that allow the caliper to move perpendicularly to the disk, thus perfectly self-aligning to the disk and granting a constant and well-balanced braking on both friction pads. Besides, with this configuration, the thruster weight does not burden on the friction pads but on the fixing structure of the caliper.

All cylinders of the new M.W.M.Freni Frizioni range are made of light alloy. The old diaphragm seal has been replaced by a rubber seal (UM), solution that, with the same performances, allows increasing the number of manoeuvres, optimizing weights, overall dimensions and air consumption, besides making maintenance easier.

In the brake calipers PPA and PPB series, the central-support modular system couples the highest performances and the small overall dimensions with the possibility of configuring the brake caliper simply. It is sufficient to replace the central body to vary the thickness of the brake disk or to replace the thruster if the use conditions change, without substituting the entire caliper.

The new patented system with double lever and central support allows, in fact, obtaining over 25 different configurations using a single caliper.

Customizations for excellence brands, too

Customization is a real strong point for M.W.M. Freni Frizioni, aimed at granting each product its excellence form, tailor-made for customers, to help them in satisfying their needs.

This is an as important target to grant the mastery of the essential competences to everybody.

«We are very flexible; our standard production corresponds to about 60%, the remaining 40% is special and tends to increase. – explains Sergio Sartori. – Special sometimes means even a single piece; it is a high-cost service, it needs design and study, the customer’s approval, the application verification and more. We have just fulfilled a particular application for Thyssen Krupp in Liechtenstein for the automatic transmission of a vehicle. I saw the driver travelling with his hands up, guided by the satellite. A great satisfaction indeed!»

Other important customizations were accomplished for the MOSE (Electromechanical Experimental Module) project, work of civil and environmental engineering, still in implementation phase, aimed at the protection of Venice and of its lagoon from the high water.

At Teatro alla Scala in Milan, in a project of automatic remake of the scenes, M.W.M. Freni Frizioni brand ranks among the suppliers, too.

They supplied a particular electromagnetic brake for an armoured vehicle to Oto Melara; a job order for other two units, still for the same armoured vehicle, followed and a request for two clutches specifically studied.

An important work was carried out for the American Ingersoll Rand on machines intended for the manufacturing of carbon fibre fuselages; M.W.M. Freni Frizioni created a specific big-size brake assembly for these machines.

Outstanding international brands in the sector of industrial machines, and not only, benefit from the flexible competence of M.W.M. Freni Frizioni

Fifty years of experience in the sector have allowed the company to achieve significant results, both in standard applications and in the applications purposely processed by its technical office to solve complex problems and to satisfy often manifold requirements.

It is worth reminding the recent setup of excellent hydraulic brake assemblies in various sizes, intended for a test bench with a fully computerized control system.

«With the last modifications we have attained exceptional results, better than our competitors’ on a world scale – ends Mr Sartori. – These benches are conceived not only for the automotive industry but also to the producers of refrigerators, washing machines and other household appliances. In these applications, the regulation provides for testing after determinate numbers of locking interventions, it is always necessary to check the calibration. It was a committing study for us but we especially focus on high-quality customers, needing specific service».

Specific assistance means a lot of commitment; there are applications that need components able to operate outdoors, like those assembled on carousels that need protections, galvanic and heat treatments, special materials and so on.

In the sector of brakes and clutches, flexibility involves additional investments, not always predictable; therefore, the question is the following: how much does customization cost? In that context, M.W.M. Freni Frizioni represents a reality that succeeded in giving logic form to its competitiveness through suitable instruments for reducing costs, even if at high risk.

To do business implies some risks, even if calculated.

M.W.M. Freni Frizioni has accepted the challenge, conforming to the customization rules; its target has always been quality, even being aware that the latter involves a high cost, finally providing anyway positive results.