The study and research activities carried out by Megadyne with the main sector manufacturers, combined with the direct experience in the main world realities manufacturing cars and tires, have allowed the company to develop a range of specific, innovative and performing products.

The long experience of Megadyne in the field of power transmissions and the enhanced know-how, deriving from the takeover of Sampla Belting in the handling and transport ambit, has given birth to more and more complete solutions meeting customers’ needs. In particular, to a range of innovative and specific products for the automotive industry.

The study and the research, in collaboration with the primary national and foreign sector manufacturers, coupled with the direct experience in world leader companies for the production of cars and tires, have allowed the company to satisfy the current performance requirements of the used products and to develop new technologies for the future.

In particular, the new lines of conveyor belts Feltcon, Fabcon, Pucon and Pvccon have been designed and implemented for the various machining phases in automotive ambit.

Not only for the transport of sheet metals and tires

Feltcon conveyor belts stand out for their high resistance to high temperatures, to abrasion and cutting; for this reason, they are widely used for the transport of steel sheets before the painting and pressing stages. Made of felt, they preserve their bearing superficial structure in time, granting precision in cutting and absence of sheet metal damaging during the machining phases.

The product line called Fabcon is instead designed for the machining and the transport of tires, from the compound to the finished product and its stocking. The specific treated fabrics of the coating assure in fact the easy detachment of compounds in machining phase. The range includes various types of coatings made of polystyrene fabrics with impregnating treatments granting the removal of the machined product.

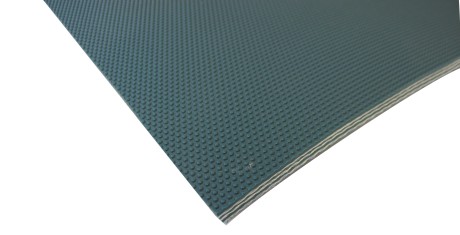

For the assembly phases of chassis and their handling, Megadyne has finally designed, developed and manufactured the lines Pucon and Pvccoc. They are antistatic belts, resistant to abrasion, cutting and oil, which stand out for the high fabric stability and the maintenance in time of the original features of the transport coating. The Pucon line shows a polyurethane coating while the Pvccon line features a PVC coating.

To assure the highest quality, all Megadyne products are certified in conformity with the primary certification standards on a world scale.