Lorenzo Attili –

A novel system for automated handling.

The Italian company Metal Work presents V-Lock. At first sight this might appear to be just one of the many catalogues of pneumatic components. It is in fact a quantum leap in quality and an upward shift in specific technology. It contains no element which alone represents a striking innovation, but as a whole it is extremely novel.

To explain this system, let us start with the problem that needs to be solved.

Anyone needing to make an assembly machine has to choose the single components and decide how to fix them all together. A huge number of slides, grippers and other components is available on the market, but the designer has to customise everything. He has to develop the devices required to connect the components together and fix them onto the machine.

He then has to design and build the adaptors, such as brackets and plates. All this requires considerable time and money, entirely disproportionate to their actual worth.

The solution to the problem

This is where V-Lock comes in.

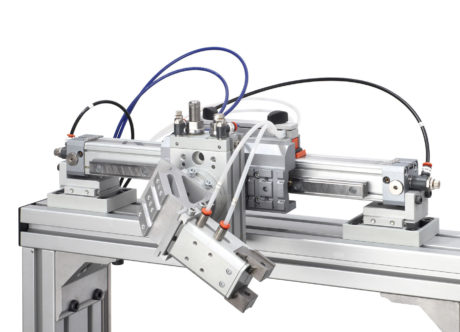

– It can connect anything to anything: grippers, slides, rotary actuators or guide units, or even aluminium structures of any make.

– It can have any spatial orientation.

– It is very easy to connect, quick to lock and accessible from all sides.

– There is no need for adaptor plates between components.

– The connection is extremely robust.

– The system is precise and repeatable, so when a component is removed for maintenance, it can be repositioned precisely.

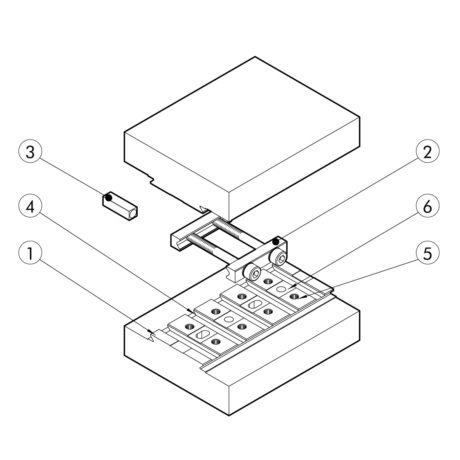

All the components in the V-Lock series have dovetails on the coupling surfaces that are 40 mm wide and extend the entire length. There are longitudinal precision slots, 6H7 wide, 20 mm pitch. To connect two components, merely bring them into contact and tighten the M5 screws in the universal fixing element, called K due to the shape of its profile.

The continuously expanding V-Lock catalogue includes precision slides, guide units coupled with ISO15552 and 6432 cylinders, rodless cylinders, rotary actuators and grippers.

Positioning precision and repeatability are achieved transversally by means of the K element, and longitudinally by inserting the hollow key in one of the 6H7 slots. Another system is used if fixing is required in a free longitudinal position that is not linked to a set value of 20 mm between slots. Such a system is called Quick-set®. It does not give positioning precision or repeatability but it does give total freedom in determining the fixing point.

The V-Lock system comes with a series of modules and accessories, such as cross adaptors, 45° and 90° squares, that are designed to allow free positioning of the components. V-Lock can be connected to any structure made up of extruded sections, such as ones by Bosch, Metra and Item. A single universal adaptor is used to fix any V-Lock component to any aluminium section.

But what if you need to fix a V-Lock component to another kind of element, such as a plate, a TV camera or anything not designed for interfacing? This can be done as well. All the faces of V-Lock components have a series of M5 threaded holes, pitch 20×20 mm, and holes for diameter of 5 pins.

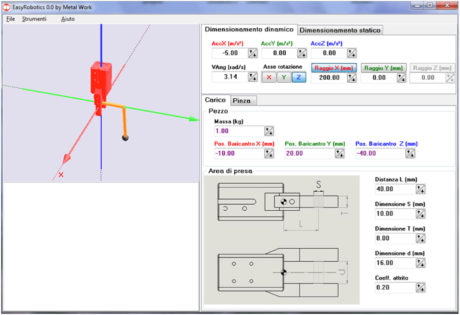

Fig. 3

EasyRobotics software for sizing and verifying systems made up of slides, rotary actuators and grippers. The figure shows a page from the SW module for calculating gripper size.