The ContiTech Power Transmission Group has expanded its range of drive belts for industry. A new V-ribbed belt is working reliably in offroad vehicles such as agricultural and construction machinery thanks to its highly wear-resistant fabric layer. The BlueConcept family, with which ContiTech provides the environmentally friendly drive for many industrial application fields, has also been expanded.

Textile layer offers protection from wear

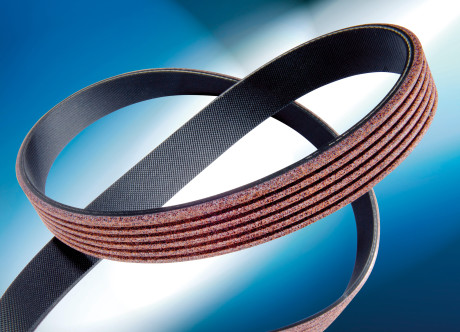

With the Unipower Tough Grip, the ContiTech Power Transmission Group now offers a new V-ribbed belt with a textile surface for industrial applications. The belt has a very low friction coefficient thanks to its pulley side, which is coated with a highly wear-resistant, dynamically extremely stable special fabric. At peak forces, the belt can thus slip briefly. This ensures a reliable drive. The textile layer protects the belt from wear, even in dusty and sandy environments. This makes it particularly suitable for accessory drives in offroad vehicles. Different tests in agricultural and construction machinery have been successfully started. The first series production approval is already available.

In the automotive industry, the Unipower Tough Grip from ContiTech has already proven its value. The fabric-reinforced belt running side ensures low levels of wear, optimum grip, and a maximum level of smooth running, even in conditions such as a cold engine start, humidity, or pulley misalignment. ContiTech produces the belt using a special, solvent-free method.

Environmentally friendly drive for all applications

The ContiTech Power Transmission Group has expanded its range of environmentally friendly applications that protect people’s health. The belts, which ContiTech offers under the BlueConcept label, aim to protect resources by using renewable raw materials, replace chemical components with natural ones, and lower energy consumption and emissions. “Judicious use of resources and environmental sustainability are cornerstones of our strategy. Thanks to the expanded BlueConcept family, we can provide the environmentally friendly drive for many areas of application in industry,” declares Regina Arning, Head of the Industry Segment at the ContiTech Power Transmission Group.

The consumer goods industry offers interesting application areas for the carbon black- and allergen-free timing belt, Synchrobelt Pioneer, whether in kitchen and household appliances, money counting devices, or the gastronomy industry. An open-ended version of the belt can also be used in door and gate systems, for example. The Conti-V Multirib Pioneer V-ribbed belt is low in pollutants and allergen-free; this makes it the ideal drive solution for the white goods industry. It is used in washing machines, for example. ContiTech currently provides the timing belt and V-ribbed belt from the BlueConcept series for original equipment. The Conti-V Pioneer V-belt is also available on the market. It is perfectly suited to ventilation systems in hospitals and care facilities, where a healthy indoor climate and pleasant temperatures are of crucial importance. The belt consists primarily of renewable resources. It contains no carbon black but is nonetheless electrically conductive. There is a new feature in the form of the heavy-duty cogged raw edge V-belt Conti-V Fo Pioneer. Thanks to its EPDM base, this is extremely temperature-resistant. It allows sustainable drive solutions to be implemented throughout the machine and plant engineering industry.

The belts from the BlueConcept series can replace all traditional belts without exception – with the same performance in strength, force transfer, and service life as their black counterparts. “The ecological awareness of users is growing. With the BlueConcept belt, we are supporting manufacturers in designing environmentally friendly drive solutions for their products,” emphasizes Arning.