Carlo Molon, Vest Inc Troy (MI) –

MDTools by Vest, Inc offers an innovative solution to design and check hydraulic manifolds. With new energy efficiency commands available the designer has more tools to help increase speed, productivity and precision in a complete and reliable software package.

Energy efficiency is a well recognized and widespread issue in the Industry and it is usually at a rather low level in hydraulic systems. At a macro level the challenge related to energy is that the understanding of energy losses in fluids also requires an understanding of fluid mechanics including the ability to analyze a system using a Finite-Element-Analysis software. Casual designers and sales engineers, who put a system together, have neither the time nor the skill to do a Finite-Element Analysis for either the whole or a part of the system.

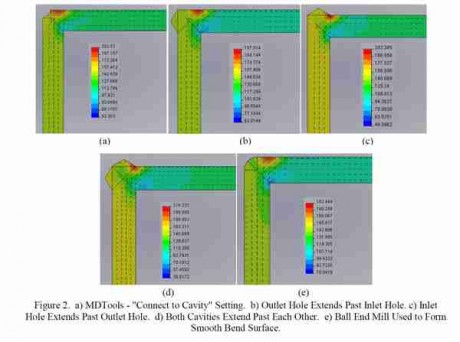

A CFD study of flows across holes in manifolds shows a remarkably graphic visualization of the many effects that cause pressure loss and energy inefficiency i.e. vortices, flow separation across sharp edges, cavitation, turbulence , boundary layer effects, high velocity profiles across a duct – all of which end up creating loss in power.

Historic approach in manifold design

Traditionally, manifold designers have designed the manifold around the hole size of the valves. If it is a ½” hole all connections are ½”. This ‘historic’ approach is weak, because it does not take into account the working conditions and also optimizes the valve block. One common misconception in the Industry is that if the cross-sectional area is the same between two passages then oil flows equally well. Often two holes of a smaller diameter with a combined area equal to a larger hole are used with the assumption that both are equivalent. This is not so because the boundary layers taken from the surface area is different between the two . When manifold designers connect flow passages, the mental construct is usually the following. That is, if the area of the opening of a hole is sufficient, then it is adequate for flow. Simulation, however, shows that the fluid surface has a strong influence in pressure drops. So a bend with a smooth turning wall causes less pressure loss as compared to a bend where drilled passages extend past tips.

MDTools approach

VEST, Inc ran extensive FEA simulations for all combinations of velocity and diameters to determine optimized pairs of hole geometry. By running simulations off-line and by building a knowledge base MDTools users are able to exploit the results in seconds while requiring no understanding of running FEA software.

A modern circuit design software, like HyDraw, allows an application engineer to capture the operating point of a valve. MDTools communicates with HyDraw and reads those operating points to guide the designer in selecting connection hole sizes. As a specific example consider a valve D03 (ISO 4401), with a capacity of 50 l/min, the average speed is 22 m/s; MDTools suggests a connection automatically resized if required by the knowledge base.

MDTools automates drilling depth, while optimizing hole intersection to ensure fewer pressure losses.

Every company has experience-based rules that help define acceptable velocities for pressure or tank lines MDTools enables a company to define its standards, and then uses the standard to graphically highlight those passageways in the design where the velocity is excessive and displays the velocity at the operating point of the system. This allows the designer to take corrective action, like increasing diameters, adding multiple flow paths etc.

This capability inside MDTools to be flow aware and energy efficient does not indicate that the system will be efficient. The control strategy, load-sense vs. displacement control pumps determines the first order of efficiency. So does the control valve sizing with generally larger valves indicating lower transmission loss. MDTools takes a given circuit strategy and size, and lowers the transmission losses. Every little feature of MDTools saves a few fractions of a bar resulting in an improvement here and another there/elsewhere. In the search of energy efficiency every part of the design must consciously contribute to raise overall efficiency.

Optimizing manifold design, without errors

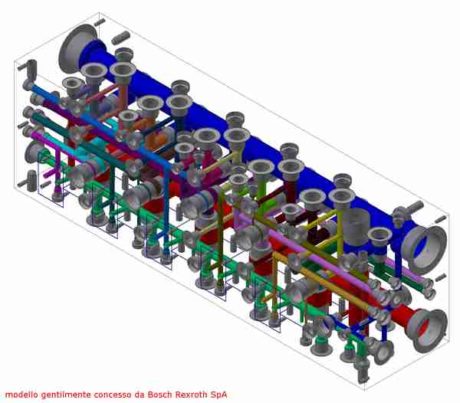

Energy efficiency is one additional feature added to the incessant development of MDTools, the manifold design solution integrated into a 3D environment developed for the first time in 2003 by Vest, Inc. MDTools is available for Autodesk, Inventor and Solidworks and brings really powerful tools to automate the design, testing, documentation and modeling process of a hydraulic block of any size. With MDTools you can easily and quickly design large and complex error free manifolds, checking and measuring wall thickness, incorrect links, missing or bad quality connections.

MDTools enables an optimized internal channel view by using different colors for each net. In this way, every network is clearly distinguishable from the other, the command ‘connect to cavity’ connects various parts of the circuit and raises a warning in case of incorrect intersections. The complete cavity library with data from major fluid power OEMs is fully configurable and allows you to add, modify, or customize new cavities, o-ring, footprints while organizing them into folders. MDTools adds an intuitive menu with a wide range of commands optimized for people designing hydraulic blocks. Everything is organized for an easy access to all the useful functions.You don’t need to be an Inventor or Solidworks expert: simply use the MDTools ribbon menu.

3D model environment

It is possible to rotate footprints, change face to a cavity, swap two cavities, add inclined holes manually or automatically, insert plugs, orifices, counter-bores, o-rings grooves and much more. Each function makes the designer’s job precise, fast and productive. During the design process you can check or measure wall thickness, check for wrong or bad quality connections, assess manifold manufacturability and much more. And all this in a 3D environment while using the latest CAD technology.

MDTools makes manifold design safe and precise while guiding machining drawing creation. With a few settings MDTools automatically creates a machining drawing with manifold views, machining chart, position and name of the cavities, cavity list, list of connections, plugs, stamping tables and much more. All the relevant information is read directly from the 3d model, without errors and without any loss of time.

For the assembly environment, MDTools helps the designer with an automatic plug insertion and an intuitive interface guiding the association between valves and cavities. HyDraw users have the possibility to create a fully automatic design starting from a schematic.

MDTools is compatible with HyDraw, the hydraulic circuit design solution of Vest, Inc and reads relevant circuit information (cavities, operating points, net lists, valves 3d models) thus saving additional time for the design process. MDTools is a product of Vest, Inc.

For more information: www.fluidpower.it