mayr power transmission has its eyes firmly fixed on the sustained trend for automation and the high demands placed on robotic solutions. For this reason, the company has substantially expanded its performance spectrum of clutches, couplings and brakes. Furthermore, mayr power transmission is presenting new, intelligent ROBA-brake-checker module designs, which are able to monitor and supply safety brakes without the use of sensors. Using these designs, new possibilities for brake monitoring are opened up – in particular also for applications in the fields of robotics and automation.

The degree of automation is increasing, humans and robots are cooperating more closely – in all the important industrial branches robots are on the advance. Machines and systems are increasing in performance density as well as operating speed and this also means higher demands on individual components. For this reason, mayr power transmission, the specialist for safety brakes, torque limiters and shaft couplings from Mauerstetten in the Allgäu region of Germany, offers small, high-performance safety brakes, for example with the ROBA-servostop construction series. These brakes are tailored to robotic requirements through their slim design and low weight. In addition, the company has a fluid-free linear brake in its portfolio with its ROBA-linearstop in electromagnetic design, which has been designed to secure gravity-loaded vertical axes. These brakes are used in applications in which compressors or units for compressed air or oil hydraulics are not available or are unwanted, such as in medical technology or the food or pharmaceutical industry, where high hygiene standards are required. The ROBA-brake-checker module now opens up new possibilities for brake monitoring also in these application fields. With a new module design and thanks to even more accurate evaluation, it is now possible to also supply and monitor small brake sizes from a braking torque of 0.7 Nm. This makes the ROBA-linearstop not just the only electromagnetic rack and pinion brake on the market, but it also means it can be monitored even in small construction sizes with the aid of the module.

Sensorless brake monitoring, reliable even in adverse ambient conditions

The intelligent ROBA-brake-checker module works without the use of sensors. Instead, it detects the movements of the armature disk by analysing voltage and current, and knows what condition the brake is in at all times. In addition to switching condition, temperature and wear, it also monitors the tension path or tensile force reserve, i.e. whether the magnet is still able to attract the armature disk. With this module, mayr power transmission is the only company to have an intelligent solution for the sensorless monitoring of electromagnetic brakes in its standard portfolio. The ROBA-brake-checker can be integrated easily and quickly into machines and systems and even existing installations can be retrofitted without any difficulties. The module represents a cost-effective solution, especially for small quantities. The fact that brakes in standard design are used for monitoring with the ROBA-brake-checker not only offers advantages in terms of costs and delivery time, but also for example with regard to corrosion protection as the brakes can be painted over easily, quickly and safely – for example, if the corrosion risk is very high and protective measures are required in compliance with the DIN EN ISO 12944 standard Protective Measures (C5), for example on wind power plants or on applications in the maritime sector.

Complete solutions from a single source

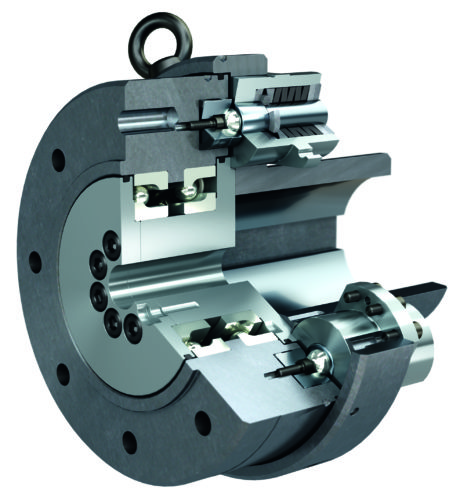

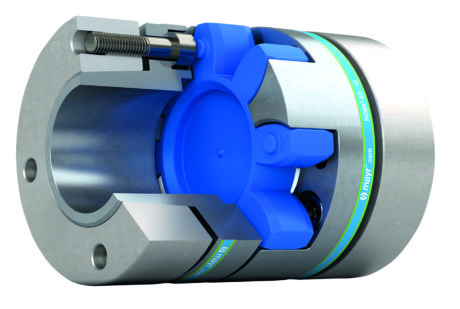

In addition to safety brakes and the associated control and monitoring modules, mayr power transmission has for decades developed and manufactured its tried and tested torque limiters and shaft couplings, and represents reliable complete solutions from a single source. To uphold this claim, the company has also substantially expanded the performance spectrum of its torque limiters. The new construction series of EAS-HT High-torque element clutches, for example, not only convinces through its improved performance density, but also stands for a substantially wider selection of possible bores. In addition, the company has launched a new construction series of EAS-Compact overload clutches, into which it has incorporated its years of experience and know-how obtained from numerous test series. The clutches thus cater for consistently increasing demands on speed and dynamics. Furthermore, the EAS-HSE Highspeed element clutches for high-speed applications have been extended by two small construction sizes. In the field of shaft couplings, mayr power transmission has amongst other things enlarged the speed range of the large ROBA-DS disk pack couplings, and is therefore able to offer reliable connections for measuring flanges for ranges larger than 100,00 Nm. And in the field of backlash-free, high-performance servo couplings, the company is permanently extending its standard modular system. New, modern production procedures also ensure favourable prices and short lead times.

See also the new mayr video portal