As a supplier of electric motors production lines, inspection is the priority for Dema to ensure the zero defects policy, mostly in a very demanding sector such as automotive.

Dema is more and more engaged in the development of lines used to produce electric motors for both hybrid and Electric Vehicles.

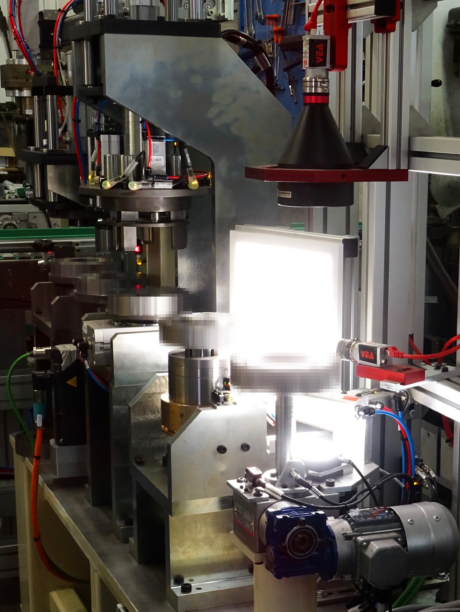

Presently, Dema is delivering two inspection lines to check rotor and stator laminations stacks immediately after their production; the lines are used to control the production process and to check that the stacks features are correct. These are the first steps of the assembly process to produce the powertrain unit of an innovative Electric Vehicle.

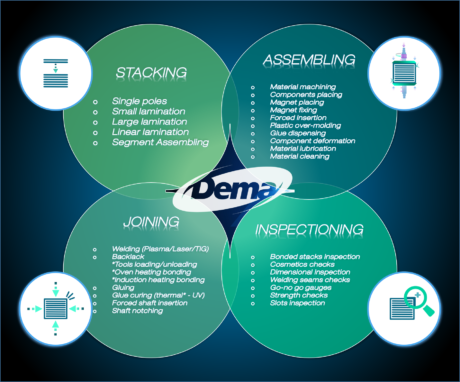

Inspection is a strategic activity in the automotive business to guarantee zero defects; for this reason, Dema has, in the past few years, developed new inspection machines dedicated to check any kind of stack features, including stack height measurement, surface run-out control, welding seams checks, visual checks, cosmetics checks, go-gauges controls on ID, OD, hairpins or magnets slots and more.

The Dema business is focused on laminations and laminations stacks handling. They are worldwide expert on stacking, joining, assembling and inspection.

That means that Dema, thanks to its experiences and its competences, can supply production machineries able to process any lamination dimension, shape and thickness, able to use any joining technology, including bounding technologies, able to produce the full assembled rotor, able to produce the joined stator stack and able to check any kind of components features.

A winning partnership for automotive

To be closer in line with their customers’ expectations, Dema announces their recent partnership with Comau, one of the current leaders on production and assembling lines in the automotive business.

Comau, with over 40 years of experience in automation and powertrain assembly , will be the right support for the new production requests in electrification projects. Comau, through flexible, modular and scalable assembly systems, grants the highest performance, process repeatability, flexibility and reliability.

With its global footprint, Comau can supply a full system dedicated to EV motors and their project management excellence ensures the added value that customers desire.

Thanks to this, the powertrain unit producers and their suppliers can be in touch with a leading team involving the experts of each process step.