With a continuous focus on energy efficiency, Mattei offers a software that optimises the use of compressed air, reducing consumption and costs

Mattei Intelligent Energy Management (M.I.E.M.) is a software that analyses energy consumption datasets of a compressed air production plant with the aim of capturing the complete energy usage profile of the air to give accurate advice on the energy efficiency of the plant and how to implement improvements.

The leading manufacturer of industrial compressors for almost 100 years, Mattei stands out from other industry players for the exclusive rotary vane technology which guarantees a higher air retention rate. The low rotation speed, up to 1000 rpm and the 1:1 ratio between the speed of the motor and the compression unit, delivers very high efficiencies and a reduction in energy consumption and costs.

In recent years, Mattei has further strengthened a green philosophy which has led to the design and realisation of cutting-edge solutions and tools that are always at the forefront.

Mattei proposes M.I.E.M. in full accordance with the company values: «This is a proprietary software that delivers very accurate and detailed information on the energy consumption of the compressors. Thanks to simulations based on the status quo observations of plant operations, it can provide more energy-efficient solutions in terms of the air compression process», explains Fabio Farneti, Mattei After Sales Manager.

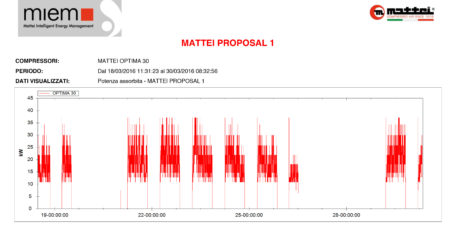

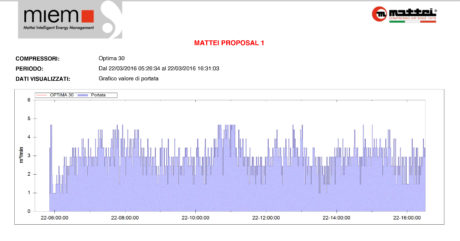

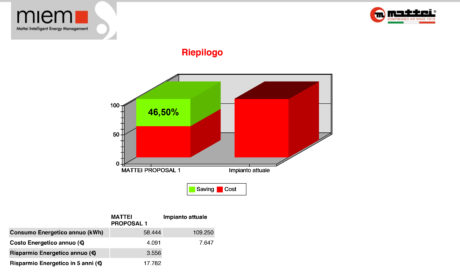

He continues: «In the first phase a registration campaign is carried out at the plant during operations. The Mattei technicians gather all the electrical parameters from the machines within the plant. The registration process lasts several days, often including weekends to detect low-battery operations data and thus provide an even more accurate evaluation, highlighting any air loss in the plant. This is where the M.I.E.M. software comes into play, processing the collected data and providing the end user’s energy profile based on the settings of the central compressors. This energy profile is simulated on the basis of experimental numerical data, in relation to actual energy consumption and operating pressures of the plant under analysis. The simulation is conducted optimising the collected data and provides a solution that, as a first requirement, reduces the energy consumption compared to the current system».

M.I.E.M. provides all the useful insights in order that the daily air demands for an industrial plant can be flattened and optimised, ultimately improving the efficiency. «We have demonstrated that thanks to the MIEM analysis, energy consumption can be reduced up to 35%. Combining the analysis with the use of the Mattei supervisory systems range, which minimise daily stoppages caused by fluctuating flow rates, overall plant efficiency improves even further», continues Fabio Farneti.

There are two supervisory air management systems offered by Mattei. Concerto, which can simultaneously control and monitor up to 16 units, and Quartetto, which allows the management and optimisation of groups of compressors with up to four connected units.

«The analysis of a plant, first with the M.I.E.M. and then it’s management with a supervisory system, combined with machines with better energy-related features, improves the company’s energy profile achieving immediate results through significant energy savings», concludes Fabio Farneti. «Furthermore, the optimisation of the number of compressor start-ups and limiting idle runtimes, allows a more regular use of the compressors, resulting in reduced maintenance costs».

Further information on the M.I.E.M analysis software and the Mattei supervisory systems can be found at the following links: