The range of vacuum generators by Vuototecnica is broad and satisfies the requirements of all users. Different generators are available according to their function (single-stage and multi-stage), flow rate, installation position, (weight and overall dimensions of the generator) and to the work environment (indoor/outdoor, dusty, wet and so on.). Among them, whose specifications can be assessed by browsing the catalogue “Vacuum Solutions”, stand out MSVE 20, the recent novelty in the family of MSVE multi-purpose vacuum generators.

Flow rate size: 20 mc/h

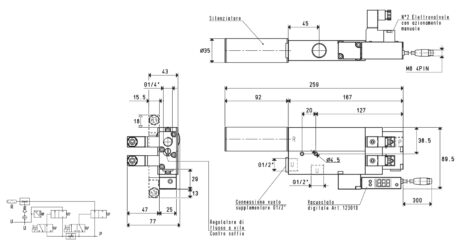

The novelty of the new MSVE 20 resides in the flow rate size: 20 mc/h. This characteristic makes it ideal for all those industrial machines equipped with a certain number of suction cups, also with big diameter, like for instance cartoning machines for the gripping and opening of cardboards, as well as machines for gripping building and/or construction materials and, in general, combined with Vuototecnica two-bellows suction cups, for gripping heavy loads and/or oily sheet metals. All vacuum generators of this series are particularly suitable for the automation of suction-cup gripping systems, to handle sheet metals, glasses, marbles, ceramics, plastics, cartons and wood, and in the industrial robotics sector, which needs systems with excellent performances combined with small sizes and weight, to be installed in whatever position.

Compressed air supply through coaxial shutters

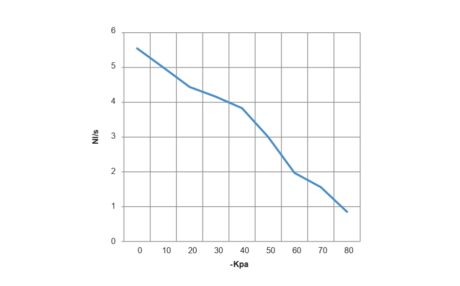

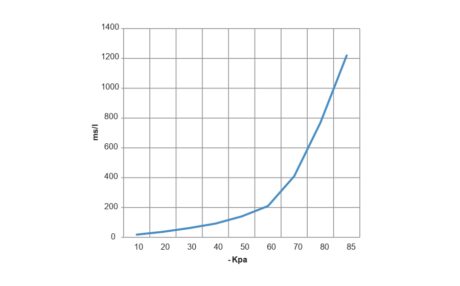

The original system of compressed air supply through coaxial shutters allows the delivery of big air quantities to ejectors and ejection system, for faster load gripping and release. MSVE, equipped with single-stage ejectors, have very high emptying speeds related to their suction capacity. Very high speeds are at stake, to full benefit of fast and performing work cycles. Besides, the check valve, integrated on the suction connection, assures the vacuum maintenance in operation, even if the electric current is missing. Under fully safe conditions and with great saving of compressed air. Two micro-solenoid valves manage the compressed air supply to the vacuum ejector and to the exhaust blower, the latter adjustable by intensity and duration, through a screw flow regulator. Activating, in fact, the micro solenoid valve for the compressed air supply, the generator creates vacuum for use.

“Energy Saving” dev

ce

Equipped with its “Energy Saving” cable (optional), when the set value is reached, the pneumatic pumpset intervenes on the electric coil of the micro solenoid valve, cuts off the air supply and restores it only when the vacuum value decreases under the minimum value. This modulation, besides keeping the vacuum degree within pre-established safety levels (hysteresis), allows a notable saving of compressed air. A second signal of the pneumatic pumpset, it too adjustable and independent from the first, can be used to enable the cycle start when the reached vacuum degree is suitable for use. Once ended the work cycle, the micro solenoid valve for the compressed air supply to the generator is deactivated and simultaneously it is activated the ejection micro solenoid valve for the fast recovery of the use atmospheric pressure. A digital pneumatic pumpset switch with display and switching signalling LED manages the compressed air supply and provides a signal for the cycle start under safety.

Cleanliness and efficiency

Like all generators of the range, also the new MSVE 20 is provided with counter-blower (in this case further potentiated) that facilitates cleanliness and efficiency. Very useful in dusty environments, like those studded with cardboard residues, but not only: in the marble, ceramic and wood sector, too.

The new MSVE 20 is compact, it can be installed on board of robotic arms, is multi-purpose and allows compressed air saving, through the Energy saving device. It does not create load losses because, as already underlined, the check valve assures the vacuum maintenance for use, even in case of electricity lack. Moreover, it is supplied at low pressure and features record emptying speed versus the suction capacity, to full benefit of short working-cycles with high performances. Last but not least, it is characterized by user-friendly maintenance, since all parts can be inspected and made with high-quality materials.

(by Gianandrea Mazzola)