Energy loss is minimised and compressed air quality is excellent – by adding AIRficient, BOGE KOMPRESSOREN has expanded its portfolio by one of the most energy-efficient pipe systems available on the market. In contrast to conventionally implemented steel systems, the aluminium pipes and fittings are permanently protected against corrosion. The advantage when compared to plastic pipes is that they are resistant to UV radiation. In addition, AIRficient can withstand temperatures of between -30°C and +80°C. Even under the most adverse conditions, this solution thus guarantees the efficient transfer of compressed air, nitrogen and vacuums. Users benefit from durable pipes, a high degree of investment certainty and save up to thirty per cent on their total costs.

“AIRficient ensures the efficient transfer of compressed air between our high-quality compressed air systems with practically no losses thus increasing the energy-efficiency of the entire system,” explains Markus Henkel, Product Market Manager at Boge. Boge aluminium pipes meet the highest customer requirements providing stable flow rates and clean compressed air. The REACH- and RoHS-compliant pipes and fittings have a special coating guaranteeing a long service life. With a temperature resistance of between -30°C and +80°C at an operating pressure of up to 16 bar, AIRficient is more heat-resistant than pipe systems made of aluminium that are supplied by competitors. Boge provides a ten-year guarantee on material defects.

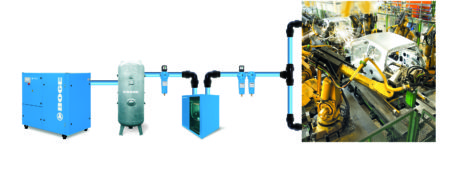

Energy flow

In comparison to standard systems, the Boge system is easier and more efficient to install. Clamping ring fittings connect the pipes on the surface. This ensures that any narrowing, that occurs on conventional, pressed pipe connections, is avoided and any loss of pressure is completely ruled out. The special coating prevents oxidation, which can consequently cause serious corrosive material damage to standard copper and steel pipes. The system is also free of oil and silicone. By implementing the Boge system, users increase energy efficiency and reduce the total costs by up to thirty per cent.

AIRficient is compatible with all Boge products. It can be used for oil-free and oil-lubricated applications in the compressed air sector. It is also suitable for transferring inert gases, such as nitrogen. When transferring vacuums, AIRficient can withstand a pressure of up to 13 mbar, while galvanised steel pipes can only reach 300 mbar.