The Italian company Oemer spa anticipates times and presents the new QS series, composed by high-efficiency compact synchronous motors that satisfy the very high efficiency requisites demanded by the “Super Premium Efficiency – IE4” regulation.

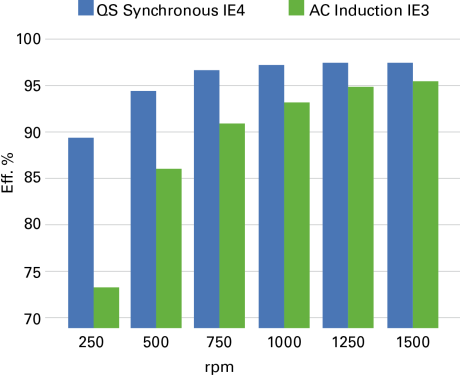

These new motors by Oemer spa, extremely compact and dynamic, develop very high performances compared to standard asynchronous motors controlled by inverters and assure the highest efficiency in the entire speed and load range.

The manufactured range currently includes five sizes and covers a power range included between 1.5 and 500 kW at 1,500 rpm, while the mechanical structure, similar to that of the asynchronous motors of the HQL series, permits the use of several shared components, thus minimizing costs and making the production flexible and modular.

The motors of the QS series provide the highest possible advantages in terms of energy saving, especially when used at partial speed and load, as more and more frequently requested in modern and efficient applications.

Besides, the technology used in these motors allows achieving much higher efficiencies and performances than those attainable with IE4 asynchronous motors, providing notable advantages both to machine manufacturers and to end-users.

VS. AC induction IE3 55 kW 4 Poles 1500 rpm.

Main characteristics of these permanent magnet synchronous motors are:

- very high efficiency in the whole speed and load range;

- high axis power in relation to the external volume;

- reduced moment of inertia of the rotor;

- very low noise;

- constant and peak torque available at zero speed, too;

- high rotation precision;

- small number of components;

- optimal cooling;

- IP 54 and IP 55 protection degree (IP 23 on demand);

- speed transducer integrated into the motor structure;

- perfect integration into the machine structure.

Typical application fields

Extruders for plastic, rubber and foods; Plastic material injection moulding machines; Metal wire working; Sheet metal working and cutting; Electric cable production; Hydraulic pumps at variable speed; Paper and cardboard production lines; Fabric treatment and working machines; Printing machines; Electric/hybrid vehicles and boats; Motor and transmission testing systems.