Pneumatic valves with poppet structures by Bonesi Pneumatik

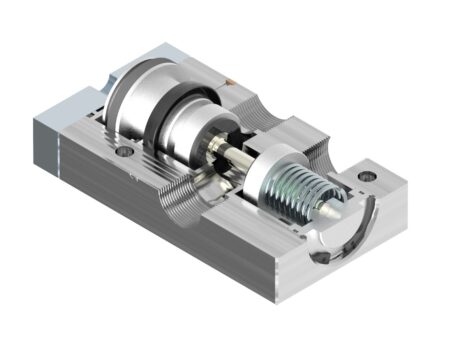

Pneumatic poppet valves were developed in Europe in the Fifties as alternative to spool valves, at that time very popular overseas. Significant evolutions were achieved also in Italy, still appreciated and up-to-date, for integration in pneumatic plants. The operation with poppet, compared to the spool one, features some advantages: more compact valve sizes, higher flow rates, faster switching times and, especially, these valves are less sensitive to the possible impurities contained in the managed fluid (typically compressed air), if not suitably filtered.

In this scenario, Bonesi Pneumatik S.r.l. headquartered at Legnano (Milan, Italy), has been an active protagonist since the dawn of pneumatics in Italy and still nowadays, in its range of pneumatic components for automation, it includes poppet valves with 1/8”, 1/4″, 1/2”, 3/4″ and 1” GAS connections with high flow rates, for both compressed air and vacuum. These valves, in the various versions, are available in 2/2 NA, 2/2 NC, 3/2 NA, 3/2 NC and 5/2 monostable functions and are used by machine and plant manufacturers in manifold industrial sectors.

They find for instance applications in cement factories, in glass processing machines, in food packaging and non-, in the Oil & Gas sector, in wood and aluminium-profile working machines, in the textile industry, in machine tools and wherever a solution developed according to customers’ requirements is needed. The Company in fact implements poppet valves with special body sizes and air connections, developed for integration into control groups upon customers’ designs, even in case of limited quantities, possibility highly appreciated by machine manufacturers.

3-way poppet valves in the pneumatic control version are particularly appreciated for applications in the Oil & Gas and Energy sectors; the sturdiness, guaranteed by the body sizes made of anodized aluminium in the standard version or, in “special” versions, of AISI316L stainless steel, combined with the use of components specifically studied to assure the full reliability in time, offer efficacious safe solutions for applications of pneumatic piloting control of actuators and valves for fluids, also in the increasingly demanded versions for low temperatures down to -40°C and for high temperatures up to +130°C.

The versions with NPT connections join the models with GAS connections. All above-mentioned poppet valves can be optionally supplied in conformity with the ATEX 2014/34/UE Directive, II 2GD classification.