(by Gianandrea Mazzola)

Available with both liquid- and air-cooling, the new range of motors series QSR SincroSPE by Oemer has been designed exploiting optimally the reluctance principle that, thanks to the elimination of rotor losses, allows a significant efficiency improvement, especially in the operational conditions of partial speed and load. Such peculiarity makes these motors able to satisfy the requisites of very high efficiency demanded by the “Super Premium Efficiency – IE4” regulation.

More in detail, such motors are provided in two different versions, depending on the particular use requirements:

- QSR/QSRa, for a variable speed use through inverter power supply, with IP 54 (QSR) or IP23 (QSRa) protection degree.

- QASR, variant with permanent rotor magnets, is instead characterized by the further increment of performances and efficiency.

If required by the application, all versions can be configured with liquid- instead of air-cooling (LQSR).

«The new series of QSR SincroSPE series motors can satisfy the excellent efficiency requisites demanded by the “Super Premium Efficiency – IE4” regulation».

Flexibility and modularity

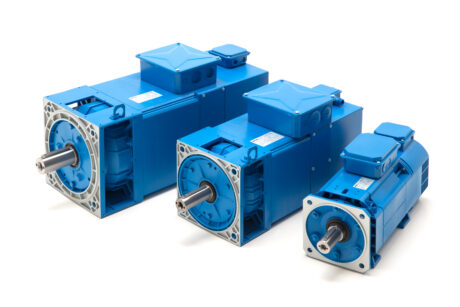

The mechanical structure of the new QSR – SincroSPE motor series, composed by synchronous reluctance motors with square lamination stack by Oemer, mirrors the one of the asynchronous motors of the HQL series, still developed by the manufacturer. This allows a flexible and modular production, thanks to the use of several components in common and guarantees the characteristic compactness and reliability of our products. Moreover, this aspect allows the full interchangeability with other items in catalogues and the possibility of customizing single motors with a broad choice of dedicated accessories.

Seven different sizes

Currently, the manufacturing range is developed in seven different sizes, with axis height of 80, 100, 132, 160, 180, 225 and 280 mm, with a power range included between a minimum of 0.75 and a maximum of 500 kW at 1,500 rpm.

The series has been devised and implemented to constitute a valid alternative of state-of-the-art square lamination motors, both as completion and as upgraded replacement on plants with already existing motors. Without mechanically disrupting the present structure.

Highlights of QSR SincroSPE motors

- High efficiency

- High power/torque delivered to the shaft

- Modern highly cared design

- High dynamic response

- Very compact overall dimensions

- Wide range of available options

Main sectors of use

- Mechanical and metalworking

- Plastic industry

- Textiles

- Iron and steel

- Traction and propulsion

- Energy production

Typical fields of use

- Plastic, rubber and foodstuff extruders

- Plastic injection moulding machines

- Metal wire working

- Working and cutting of metal sheets

- Electric wire machines

- Variable speed hydraulic pumps

- Paper and cardboard production lines

- Machines for tissue and fibre processing

- Printing machines

- Electrical/hybrid vehicles and boats

- Systems for testing motors and transmissions