Founded in Sassuolo in the 1970s, A-Zeta Gomma is a company specializing in the manufacturing and marketing of rubber, PVC, and PU conveyor belts and drive belts. Its story resonates with numerous other businesses that have contributed to the success of the Italian industry. Initially established as a small artisanal enterprise by Maurizio Pistoni, who currently serves as President, the company has experienced rapid growth and evolved into a trusted partner for major companies within the Sassuolo ceramic district in Modena, Italy. This district is renowned globally for its manufacturing, allowing A-Zeta Gomma to expand its presence both within Italy and internationally, as well as develop expertise to offer products and services to various industrial fields. To delve into this journey further, we spoke with Alessandro Pistoni, the son of Maurizio and the company’s Operations Manager.

How is the company structured in terms of logistics and manufacturing?

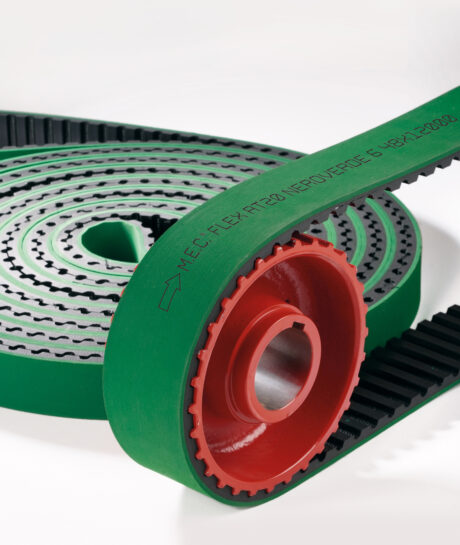

Our manufacturing hub remains in Sassuolo, where we operate three manufacturing units, administrative offices, and a warehouse capable of processing an average of 6,000 belts per day, resulting in an inventory of 80,000 articles readily available. Our product range serves over 2,500 customers and partners, offering V-belts, rubber, PVC, and PU conveyor belts, thermo-weldable belts, roller coating hoses, rubber sheets, rubber molded items, technical components, and equipment for belt pressing, welding, and junctions.

What industries do you cater to?

Despite facing economic challenges in recent years, for reasons well-known to all, our numbers have continued to grow. Our annual turnover exceeded twenty million Euros, and our workforce comprised over one hundred employees and collaborators in the previous year. These figures are largely driven by our historical core business in the ceramic sector, which now accounts for 30-40% of our total operations. Over time, we’ve diversified our portfolio, establishing significant collaborations with other sectors, such as agrifood, woodworking, packaging, as well as supplying mechanical and paper manufacturing companies and the broader industrial landscape.

In your view, what are the key highlights of A-Zeta Gomma?

Our approach has always been forward-looking, with a keen focus on the potential directions of our target markets. We have made decisions that run counter to prevailing trends when necessary. For instance, while many companies in our sector turned their attention to China and India in the early 2000s, we opted to invest in Italian manufacturing without delay. We undertook a comprehensive reorganization of our departments and product lines to diversify our offerings and serve additional sectors beyond ceramics. We also became early pioneers in data analysis and digitalization, anticipating the advent of Industry 4.0.

Operating in the heart of the esteemed Sassuolo district has added value by enabling us to explore foreign markets. As a partner to numerous local machinery manufacturers that export globally, we have extended our reach overseas. Today, exports contribute approximately 20% of our turnover, with significant shares from Spain, the United States, and the Arab Emirates.

Our approach is to position ourselves as specialists in our products, primarily catering to machinery manufacturers with a strong focus on service and design capabilities. Our business vision has consistently guided us to produce a select range of items with a broad and diversified assortment. Notable among our strategies is the acquisition of Nittra in 2006, a company in the lightweight belt conveyors sector, which promptly bolstered our product offerings, including conveyor belts for handling raw materials from ceramic production, right through to installation. These strategies have collectively contributed to making our company robust, versatile, and dynamic, enabling us to not only receive excellent market feedback but also weather these challenging economic years with success.

What is your service concept?

Our commitment is to offer cutting-edge solutions to our customers by focusing on the ability to customize products, which we can manufacture based on technical designs and specifications provided by our customers. Additionally, our control over all production processes allows us to address complex requirements while offering pre- and post-sales support, including a dedicated division for technical consulting aimed at process optimization and ensuring optimal performance. Furthermore, a portion of our staff is dedicated to providing round-the-clock assistance, even beyond the product warranty period, to resolve any issues that may arise.

What are the company’s prospects for coming years?

Certainly, our ongoing commitment is to continue investing in Italy, particularly in expanding our technical office’s capabilities for product customization, alongside a growing emphasis on response flexibility and promptness. We will also continue to invest in digitalization and closely monitor our competitors, as these factors remain fundamental to our future success.