The Italian company Metal Work specialized in the production of pneumatic components for industrial automation, releases a new electronic pressure regulator, component that enriches the offer of its electro-pneumatic EB 80 system. The device, designed to adjust pressure with extreme precision, is fully integrated into the isle of solenoid valves and stems from Brescia company’s long-term expertise in the development of electronic precision products.

Countless combinations

EB 80 electro-pneumatic system, backed by an outstanding commercial success, consists of a range of products studied for the control and the regulation of a pneumatic system, all embedded into a single expandable and reconfigurable module. In a single device, it is possible to insert electro-pneumatic valves of all kinds, multiple-position bases, pneumatic power supplies and power supplies, modules for the management of input or output signals – in both cases, both digital and analogue – and other numerous options. EB80 can be also combined with drives or motion controllers for the control of electric motors and it is provided with a sophisticated diagnostic system in conformity with Industry 4.0 principles. The countless possible combinations can be achieved with a limited number of base components, so facilitating also the selection by the designer who chooses EB80. To hit such target, the company has manufactured a single size of valves that combine small sizes with great performances, besides the capability of serving most applications. EB80 is also characterized by the modularity of components and the flexibility in the system composition: peculiarities that allow inputting, removing or displacing modules according to the requirements, adding new functions and changing the type of control.

Series Regtronic

EB80, in the version with multipolar control, allows the control of a maximum number of 38 electro-pilots (which correspond to 38 monostable valves, 19 bistable or a combination of the two) whereas in the version with fieldbus it can manage up to 128 electro-pilots. The flow rate of standard valves reaches up to 800 Nl/min; for bigger flow rates, and without changing size, high flow rate valves are used (Pat.), reaching up to 1,400 Nl/min (other feature that makes the EB80 system unique).

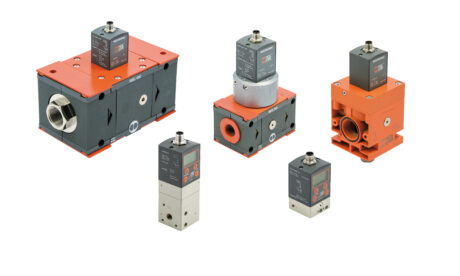

Due to the great potentialities of the EB80 system, the company’s commitment to the development of new integrated components was natural, precisely like the new electronic pressure regulator that allows a control of such magnitude in the order of few dozens of millibars. Metal Work has been developing for a long time a broad range of electronic regulators, with very high precision features and flow rates that go from 10 to 20,000 Nlitres/minute.

This product range, framed in the Regtronic series, features miniaturized regulators with M5 threads to satisfy the requirements of small overall dimensions, medium-size regulators, with 1/8” or ¼” threads, for the most frequent uses, to reach then regulators with 2” threads for those needing high airflows. All models are available in the version with display and control keyboard or with M12 connector for remote control; they can be chosen in the version with analogue control system or in IO-Link version.

Design flexibility

EB 80 constitutes the “brain” of the electro-pneumatic system and represents the centralized control element of the whole pneumatic plant. In case of applications needing high precision in the pressure regulation, the comfortable integration into the central system of one or more elements able to fulfil such function grants the plant designer an otherwise unfeasible flexibility.

In that way, with an integrated device we can perform, besides all renowned peculiarities of EB80, also the new very useful function of precise pressure regulation. The new element maintains the whole modularity and flexibility that characterize EB80 and therefore it can be easily inserted or displaced inside the isle; dimensionally, it takes up the space of a 4-position base and it is suitably designed for integrating up to 16 elements of this kind inside an isle. From the functional point of view, the new component is proposed in two versions: one version, said for “local” regulation, which checks the pressure level at the output positioned on the base of the same element and one version for the adjustment in “series” of all elements of EB80 isle positioned on the right of the component itself.

Two versions

The first version is useful for the punctual pressure regulation, detected at a single output and generally used for a single element or for a plant branch; it also allows achieving a good flow rate of the regulated air.

The typical example of that use is when it occurs in the pressure regulation at a dispenser or at a single actuator, in very precise manner. The second version is instead used when you want for instance to adjust the pressure at all valves inside the isle, from a certain point forward. For example, when a first part of the isle is used for the control of cylinders that work at a certain pressure, and only from the regulator onwards, you need to control actuators that work at a determinate very precise pressure; or to change the pressure dynamically, inside a working cycle, by means of a control signal. From the control point of view, both versions can be integrated both into isles with fieldbus and into isles with multipolar control.

The versions for isles in fieldbuses are checked by the terminal itself of the isle, whereas the versions for multipolar isles are equipped with their own M12 connector for the electric communication. Like for other electronic regulators by Metal Work, also the newborn is available in the version with display and manual control keyboard or in the version for remote control (without display). The new electronic regulator as well, like the rest of the isle, features IP65 protection degree as standard: to obtain such feature without losing in precision, each regulator is equipped with a compensation system of internal over-pressures able to maintain the protection declared.