The secret is in the air. Air actuators generate effective lifting and pressing forces. Air springs increase riding comfort in industrial vehicles. Furthermore, robust construction and longer service life are allowed.

Whether it is in forklift trucks, conveyor belt systems, or machines, ContiTech air springs and air actuators also fulfill a wide range of applications in internal logistics operations. Their unique product features and long service life are particularly evident when the going gets tough.

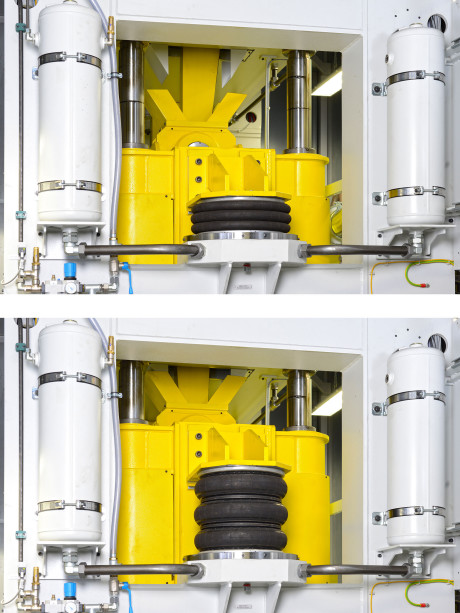

As pneumatic lifting and press cylinders, air actuators perform difficult jobs in the area of machine and plant engineering. In internal logistics operations, for example, they have stood the test on transport systems in parcel sorting centers. Their robust and simple design gives them an edge over conventional pneumatic cylinders in many applications. They are a wise choice where clearances are tight and adverse ambient conditions prevail. ContiTech can supply pneumatic cylinders with diameters ranging from 60 mm to 1000 mm and a standard pressure of 8 bar. They have a lifting power of 0.5 kN to 440 kN. Designs for operating pressures of up to 16 bar are also available for special applications.

Air spring systems: effective in anti-vibration technology

ContiTech air spring systems are used to dampen vibrations in mounting and bearing systems, where their excellent performance, reliability, and cost-effectiveness have been shown to be quite valuable. They are used in both heavier installations and in industrial vehicles like forklift trucks. They successfully reduce vibration as well as noise, thereby ensuring smooth transport and good riding comfort – both for the driver and the cargo.