ATAM has recently presented a new range of coils featuring an external armature for high demanding applications and a new family 455 explosion-proof solenoid.

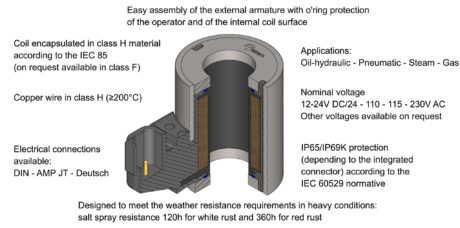

The Italian company ATAM presents its new range of coils, the series 471, 472 and 473. The coils are offered with the 3 different external diameters of 37 mm, 45 mm and 65 mm, and with different electrical connections, DIN, DEUTSCH and AMP JT, to meet several customer requirements.

The new family of coils has been designed for use in all applications where very high resistance under highly demanding conditions is required, such as in case of extreme temperatures. The coils feature an external armature that protects them against physical damage and improves the magnetic flux; IP65, IP67 and IP69k protection degrees, depending on the electrical connection chosen by the customer; a salt spray resistance for the white rust of 120h and for the red rust of 360h.

The series 471, 472 and 473 coils are encapsulated in a high-quality plastic material with a Class H thermal resistance.

The technical interaction between the development and the production of encapsulated coils and industrial connections, together with a state of the art test lab, allow ATAM to simulate the combined use of the 2 products in every condition, thus allowing the company to offer optimal solutions in terms of reliability, quality and convenience.

New family 455 explosion-proof solenoid

ATAM has also launched a a new range of 3 solenoids for potentially explosive environments, each of which has different levels of ATEX and IECEx certifications.

The highlight is on the model 455 solenoid which features an explosion-proof case and ATEX and IECEx certifications for gas and dust for zones 1 and 2. This model is addressed to highly demanding hydraulic applications.

The model 455 solenoid stands out for its important characteristics that make it totally safe in potentially explosive atmospheric applications, such as those found in mining.

The model 455 solenoid by ATAM features a low carbon steel micro-fusion casing. The body as well as its end flanges are Zinc-Nickel plated, offering high corrosion resistance.

Voltages are available between 6 and 240 V following customer requests, both in DC and AC voltages. The solenoid can operate with a working pressure of 350 dynamic bar and in an environmental temperature range between -60° and +80°C, in T4, T5 and T6 temperature classes.

The model 455 solenoid with ATEX and IECEx certifications can be supplied with or without cable in order to allow customers to connect the solenoid with the most adequate cable in accordance with applicable market regulations.

The new families of ATAM products are the result of technical interactions between their development and the long-standing production experience gained in manufacturing encapsulated coils and industrial connectors, together with our state of the art test laboratory that allows ATAM to simulate the combined use of the 2 products in every condition, thus offering our customers optimal solutions in terms of reliability, quality and convenience.