Forty years of experience and specialization in the field of hydraulic cylinders characterize the Italian company Conforti Oleodinamica.

A new and more aggressive industrial model identifies a development driver in the competitiveness of both suppliers and of their customers; the shared communication is involved in that context, too. In other words: there is nothing better than Knowledge shared out in a sort of ring-a-ring-a roses between customers and suppliers, which we like defining “the reality play”. A constructive ring-a-ring-a roses, rich in meaning, played in the wide-ranging area of customer service.

Target: customer and supplier mutually integrated “to exploit each other”, to coordinate the work of all, according to their own competences and to be more competitive together. Example: forty years of experience and the specialization in the hydraulic cylinder sector allow Conforti Oleodinamica srl (Monza, Italy) to offer the right mix of quality, price and service. Manufactured with notch materials on high-precision machinery, the cylinders undergo a process of controls and tests that grant the best quality and reliability constancy. The computerization of the productive process as well as a well- stocked up warehouse allow the company to provide fast and timely deliveries. Dedicated application and software packages are developed inside the company and offered to users as a valid support to the design and management of products. A technical and sales competent dynamic staff is at disposal to assure fast and customized answers. All that is more necessary than ever because power transmission components are a valid example of the force of the fluid power technique when it tries to authorize a sort of strategic technological process; “strategic” components are many but often scarcely visible. This means that the supplier must provide component users with the necessary information, thing that requires great technological and informative mastery. We need competent technical sellers, ready to cooperate with the market, since the component industry makes great strides and new solutions emerge, thanks to design instruments like CAD. While in the Sixties the fluid power technique celebrated the fashion of brute force, today the same is blacklisted among microelectronic and informatics values to be assimilated, with the whole ecologic and ergonomic potential of the power transmission.

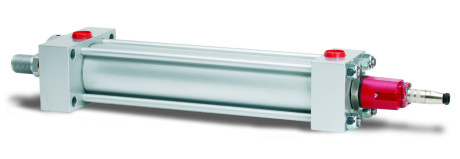

Tie rods ISO 6020/2 hydraulic cylinders

This tie-rods hydraulic cylinders conform to the ISO 6020/2 regulation, for use with magnetic sensors, too. They are available in all the anchorages that the regulation provides for, in several seal configurations. All cylinders are tested before the delivery in conformity with the ISO 10100 regulation.

For strokes exceeding 2,000 mm., it is advisable to choose the series HD/HK. ISO 6020/2 servo-cylinders are available both with tie-rods (TD and TK version) and with counter flanges (TH and TX version); they are prearranged with an electronic transducer that allows knowing the absolute rod position. The choice of the transducer type depends on the wished performances. The positioning precision is determined by two elements: the transducer resolution and the control system of the cylinder. Three typologies of transducers are provided:

– Temposonic, which allows high resolutions and various control types and can cover all necessary stroke lengths;

– Potentiometric, where the output signal is given by a cursor that slides on a potentiometric track. The tension is proportional to the cursor position; the maximum possible stroke is 500 mm.

– Inductive, which provides a tension or current signal, generated by a separate electronic circuit; the maximum possible stroke is 1,000 mm.

Servo-cylinders can be equipped with ISO interface plates, which allow the direct assembly on board of the cylinder of ON/OFF solenoid valves, proportional solenoid valves and servo-valves. This configuration coupled with a control unit assures an optimal hydraulic rigidity, which notably improves response times, the repeatability and the positioning accuracy. For a correct operation of servo-cylinders, it is indispensable that, during their commissioning, they are perfectly purged from the air present in the cylinder; therefore, these cylinders, besides the purges on the heads, have a purge grain on the rod end, which allows the ejection of the air contained in the chamber that houses the transducer. The particular position of this purge permits the operation even when the cylinder is operating, without removing the rod from its housing.

Hydraulic cylinders for heavy-duty applications

These cylinders, compliant with the ISO 6022 regulation, are available in several seal configurations, depending on the wished use conditions and performances. The use of bronze guides for the rod and the piston assures high performances and duration in time. Naturally, also these cylinders are tested before the delivery in conformity with the ISO 10100 regulation.

The servo-cylinders of the TP series are prearranged with an electronic transducer, which allows knowing the absolute rod position. The choice of the transducer type occurs according to the performances that we want to achieve. The positioning precision is determined by two elements: the transducer resolution and the control system of the cylinder. The standard transducer used is of Temposonic type, which allows high resolutions, various control types and can cover all necessary stroke lengths. Potentiometric and inductive transducers can be supplied by contacting the technical office. Servo-cylinders of TP series can be equipped with ISO interface plates, which allow the direct assembly on board of the cylinder of ON/OFF solenoid valves, proportional solenoid valves and servo-valves. This configuration coupled with a control unit assures an optimal hydraulic rigidity, which notably improves response times, the repeatability and the positioning accuracy.

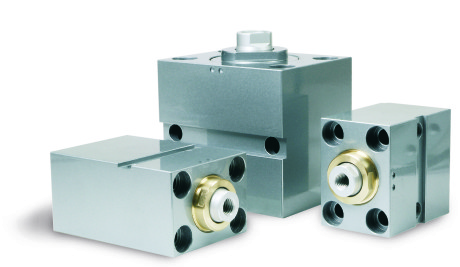

In the name of high modularity and sturdiness

A product recently introduced, very precious in heavy-duty applications, consists of compact RQ steel double-acting hydraulic cylinders, with short stroke and cylinder lock; its design is oriented to sturdiness, for extremely demanding applications, with maximum use pressures of 250 bars. Standard or not standard, the structure of these cylinders is short-stroke, with maximum stroke of 100 mm; they are very suitable for industrial automation applications, when a sturdy, compact and highly modular structure is necessary. It is available also in the version with anti-rotation device and external mechanical stroke ends for the control of the final positions of the rod.

Rotary actuators of easy maintenance

Rotary actuators generate a torque through a toothed wheel and a rack operated by a hydraulic cylinder.

That solution allows simplifying kinematic gears and especially involves easy maintenance. Rotary actuators are equipped with adjustable brakes, able to generate at the stroke end a braking torque comparable to the maximum torque of the cylinder. End stroke registers allow the timing of the system with a regulation range of ± 5°. They are available also in the version with pneumatic piston, for the use with proximity magnetic sensors along the whole piston stroke.