A company, specialized in bevel gears, which completes a standard range with a special production upon customers’ design or in-house designed to satisfy all types of requirements. With an interesting productive structure based on a network of external “carbon neutral” craft firms. They are the secrets that allow DZ Trasmissioni not to be affected by the sector crisis.

Is there the need to transmit the power of a rotary motion between two axes arranged at ninety degrees each other, even in particular and complex situations for which there are not standard products? A good solution might be to turn to the bevel gears that

has been designing and proposing for over a quarter of a century. The standard range of bevel gears includes various sizes, shafts from 8 to 85 mm, powers up to 477 kW and a maximum rotation speed of 3,000 rpm, but the Bolognese company can also study and implement special transmissions in very short times. Let’s see more from close up the history of DZ Trasmissioni, how it is organized and what are its strong points.

Linear and constant growth

Claudio Pullega, managing director in charge of DZ Trasmissioni, established the company in 1986 together with Didimo Zanetti, the entrepreneur running the homonymous company headquartered at Casalecchio di Reno specialized in the production of spur and straight bevel gears since 1946, exactly 40 years before. A curiosity: the logo of DZ Trasmissioni is not by chance the acronym of Didimo Zanetti, but if we read it backwards it becomes ZP, as Zanetti Pullega. In 1996 Claudio Pullega preferred continuing his entrepreneurial adventure alone, acquiring the shares belonging to his initial partner, who has anyway remained a primary supplier of the Zola Predosa company.

Over the years, DZ Trasmissioni has developed and can boast a turnover of over 4 million Euros in 2013 (in 2012 it amounted to 3.5 million Euros) achieved with only eight internal employees. A slow and linear growth by 10% year-on-year then, also in these difficult market times. «Concerning our productive philosophy – explains Pullega – we mainly turn to subcontractors. We have optimized the outsourcing by creating a craft fabric of small companies that almost exclusively operate for us, able to work also on Saturdays and on Sundays when there are some particular needs. This thick and well-proven network of “carbon neutral” companies allows then us to be flexible without giving up quality».

Actually, in terms of turnover and production, DZ Trasmissioni might be a company with over fifty employees. The choice of outsourcing the work, in countertendency with other similar realities to Pullega’s company, has then turned out to be winning. «We should not however forget – specifies the managing director – that lots of these companies have been working for us for over 25 years with mutual satisfaction because, instead of considering them as suppliers that it is possible to bleed white, we deem them as collaborators and integral part of our enterprise».

Therefore, in the headquarters of DZ Trasmissioni only the design, the assembly and the testing are carried out. The suppliers are anyway requested to conform to the severe corporate qualitative standards, as Pullega underlined, and they do that in virtue of a collaboration lasting for a quarter of a century.

Standard and special production

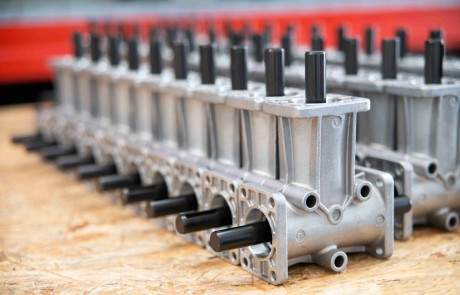

As briefly said at the beginning, DZ Trasmissioni, besides availing itself of the know-how to manufacture special bevel gears upon customers’ design, it relies on a range of standard products. In particular, in this ambit, the bevel gears of the DZ and ZP series have been designed for industrial applications where it is necessary to transmit a rotary power motion between shafts perpendicularly arranged each other. They are available in nine different sizes and they can be with two or three outputs with 1/1 or 1/2 or 1/3 transmission ratio. The casing is of stiff aluminium alloy monobloc type, with four or six attachments plans and 3/4 truing conditions. They are bevel gears, cut on Gleason machines, with spiral toothing assuring the best loading capacity.

Recently, and still in completion phase, a new standard series of bevel gears was born, with cubical shape in eight different sizes, sixteen different structural shapes and five reduction ratios. Customers themselves urged to obtain this new range, fed up with chasing technical promises never kept and intractable deliveries. DZ trasmissioni has not only merely copied the competitors’ products, but it has introduced some important novelties into the product, which can be summarized in four essential points: lighter, more precise, sturdier and cheaper. Lighter because the casing is made of aluminium instead of cast iron and on average this makes the group weight decrease by 60%, important aspect for the new energy saving requirements. More precise because the casing in a single piece, unlike the standard design in four pieces, allows higher precisions on angular backlashes and truings. Sturdier because the elimination of the usual flanges permits much wider bores, housing gears and bearings with bigger diameter while keeping the external sizes unchanged. And besides cheaper, because aluminium castings are produced with much more inexpensive standard processes than cast iron.

The strong points

But what are, in short, the strong points of the Bolognese company? «Besides the high quality that the market has always acknowledged us – ends Pullega – one of our strong points is certainly represented by fast deliveries, with orders that we succeed in fulfilling in the lapse of two weeks. Both thanks to the fact that we have a relevant warehouse for standard series and both thanks to the flexibility that our induced activities grant us. With the same speed of a job order of one hundred pieces, just to mention another recent example, we have fulfilled an order of 10,000 units for a bevel gear of the DZ series».

The market

DZ Trasmissioni operates in a market niche calling for high-quality products in not very big quantities. Two factors that protect it from the Asian competition and from big multinationals. «It is not easy to manufacture our bevel gears – specifies Pullega –if you want to maintain a high quality standard.

Some Far East companies have purchased machinery that might potentially succeed in making them, but they are still very distant from being able to use them adequately and the final result does not bother us, at present. On the other hand, we have made the precise choice of betting on high-quality products, because the competition is still fierce for those characterized by a low-level technology. It is just thanks to this strategy that we can boast a slow but progressive growth ».

dear reader

I am looking for gearboxes as shown in your paper .

Will send a seperate e-mail with the picture and dimensions.

Can we buy these in Canada. If, not can you ship to Canada.

If not, can you ship to a address in Holland and we make t part of our shipment.

thank you

Henk Rozendaal

tel 001-604-798-9229

Dear Sir,

I thank you for appreciating the content of our digital magazine Power Transmission World.

For any request about DZ TRASMISSIONI bevel gears, you could directly contact Mrs. Elena Pullega, sales manager of the Italian company to the following address:

elena.pullega@dztrasmissioni.com

Best regards

Anna Bonanomi

editor

Dear Mr. Rozendaal,

I thank you for appreciating the content of our digital magazine Power Transmission World.

For any request about DZ Trasmissioni Bevel Gears, you can directly contact Mrs Elena Pullega, sales manager of DZ Trasmissioni:

elena.pullega@dztrasmissioni.com

Best regards

Anna Bonanomi

editor

how to remove bearing from your three way gearbox that has three side