Energy efficiency of compressed air filters increased by a new filtration technology.

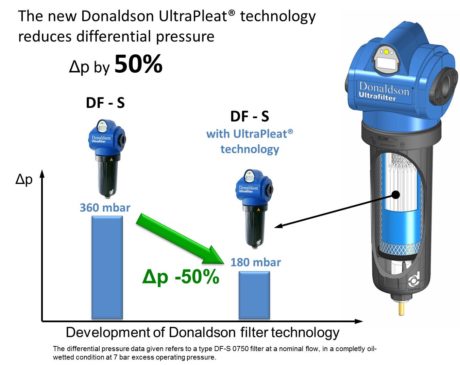

The differential pressure in filtering compressed air and gases is now being reduced by 50%, thanks to a new filter medium. This extremely favourable performance that engineers at Donaldson in Germany’s Haan/Rhld. were able to achieve by developing their new UltraPleat filtration technology has had a great effect on the energy consumption of compressors. Because compressed air is used in over 90% of production plants, compressed air filter elements make a significant contribution to the reduction of electricity costs in many areas of industry.

The Ultra-Filter housings with UltraPleat DF-S coalescence filter elements are manufactured at the Haan factory, consistently following the latest “lean manufacturing” standards. This means that the benefits of better filter performance can be passed on to customers without increasing the price level.

UltraPleat filtration technology uses a new structure of coated high-tech fibres that are processed into a pleated filter medium with a high separation efficiency of liquid particles and a huge adsorption capacity for solid particles. The multilayer structure of the new filter medium was designed so that optimal aerodynamic conditions are achieved, simultaneously providing a filter surface that is over 400% larger by comparison with wound filter media. For the separation of oil aerosols, an efficiency of ≥ 99.9% in accordance with ISO12500-1 is achieved. The filter performance data in compliance with ISO12500-1 and ISO12500-3 have also been validated by an independent institute for energy and environmental research. The fact that this high filtration performance was achieved while reducing differential pressure by a further 50% highlights the successful development of Donaldson filtration technology in increasing energy efficiency and resource conservation.

Efficiency and Sustainability

The use of this new technology is worthwhile for compressed air users, as can be seen from an example based on an Ultra-Filter DF-S1100 UltraPleat compressed air filter. If operated for 8,000 hours at a flow rate of 1,000 m³/h with the permissible operating pressure of 7 bar, a reduction in differential pressure of 190 mbar to 180 mbar results, measured in an oil-wetted condition. This corresponds to an annual energy cost saving of approximately € 1,460, assuming an electricity price of 8 cents/kWh.

The real impact that a compressed air filter with low flow resistance has on the energy consumption of industry becomes clear when considering that – on average – two filters are used for the treatment of compressed air produced by one compressor. In European industry, around 320,000 compressors consume about 80 billion kilowatt hours per annum in the generation of compressed air, which represents around 10% of industrial electricity demand[1], costing industry about 6.4 billion euro at an electricity price of 8 cents per kWh. On the basis of the utility power plant mix, the environment is negatively impacted by 47.2 million tonnes of CO2.

The rapid availability of compressed air filter elements and components is an important aspect to the trade and users of compressed air. All popular sizes and types of filters are available from stock. Orders received by 1 pm will usually be shipped the same day and a comprehensive service network provides on-site maintenance of compressed air treatment systems and offers advice to customers.

1 Peter Radgen, Edgar Blaustein “Compressed Air Systems in the European Union”/Fraunhofer ISI Press Release