Avio Aero, a GE Aviation business working on the design, production and maintenance of components and systems for the aeronautics industry, today launches in Cameri (Novara, Italy) one of the largest plants in the world designed specifically for additive manufacturing. This technology, more commonly known as 3D printing, starts from a digital model and enables any shape of solid object to be produced through a combination of special metal alloys.

Its special characteristics mean that additive manufacturing meets in full the main challenges of the aeronautics industry of the future such as weight reduction – with the aim of achieving less fuel consumption and lower emission levels – and a reduction in the production times of components using increasingly innovative and robust metal alloys. For example, producing an injector for an aviation engine combustor with conventional technology involves welding components produced separately starting with microcasts, whilst additive technology produces it directly in one piece.

With its 2,400 sqm the Cameri plant will be able to accommodate up to 60 machines for producing components using additive manufacturing. The premises also allow two atomisers to be installed for the direct production of special metal alloy powders such as Titanium Aluminide – TiAl – and two installations for component heat treatment.

Avio Aero’s commitment to growth through innovation has been constant over the years: between 2010 and 2012, for example, the company invested about 400 million euro (Capex) in the aviation business, of which 100 million dedicated in particular to Research and Development. More specifically, investment in additive manufacturing technology, including the new plant, has been in the region of 20 million euro in the past 4 years.

“In the aeronautics industry being able to count on a new technology means having believed in and invested for years in a research and development process”, stated Riccardo Procacci, CEO of Avio Aero. “The plant we’re inaugurating today is the result of the commitment and passion of our technical staff and engineers, as well as the close working relationship we cultivate with universities, research centres and the industrial fabric of small and medium size enterprises throughout Italy. It is thanks to this that today Avio Aero is taking a further step forward in designing and producing components that will fly in the increasingly high-performance, silent and lower emission aviation engines of the future”.

ADDITIVE MANUFACTURING TECHNOLOGIES IN AVIO AERO

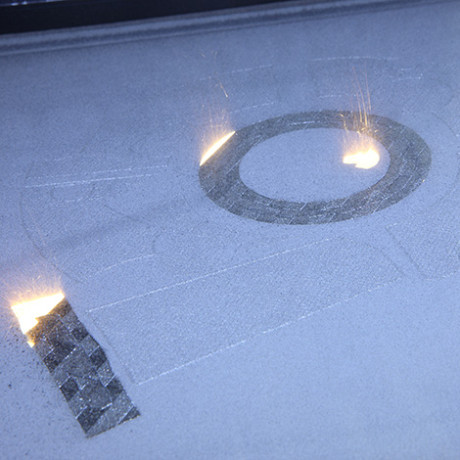

EBM (Electron Beam Melting):

- This technology uses an electron beam in the powder melt process.

- TiAl alloy metallic powders are used, intermetallic materials formed primarily from titanium and aluminium. Using TiAl allows component weight to be reduced by 50% compared with other metal alloys.

DMLS (Direct Metal Laser Sintering):

- Consists of using a laser beam to melt metallic powders.

- Is used with many metallic powders that are already available.

- It is the most widespread “powder bed” technology in the world.

In both cases, the 3D model of the component to be produced is created and transferred to the machine. This spreads thin layers of metallic powders and then melts them and builds them up layer by layer, creating the product by “Additive Manufacturing”.

THE ADVANTAGES OF ADDITIVE MANUFACTURING

- “Green” technology: there are no emissions.

- More homogeneous products with greater metallurgical uniformity.

- More robust and lighter products.

- Products produced quickly, with less material and energy wastage.

To find out more, see the video on Avio Aero’s YouTube channel http://youtu.be/MDol1oE-YSs