In the racing business, time and reliability are the key success factors. Minimal changes in a car’s construction can impact its entire performance. Our PLM software is enabling the engineers at Infiniti Red Bull Racing to accelerate product design and production processes, achieving more design iterations in the virtual environment than could ever be achieved physically,” explained Siegfried Russwurm, CEO of Siemens’ Industry Sector and member of the company’s Managing Board. “But PLM software isn’t just a plus for Formula One,” he added. “Our customers can use it in almost every industry – from ski design to industrial production.”

The Siemens software allows Infiniti Red Bull Racing engineers to design new car components, test them in the virtual domain and initiate their production and installation with a mouse click in record time. “The Siemens partnership is a critical one for us because it’s an integral part of our design process. Through our relationship with Siemens we’ve come to rely on their critical tools to generate creative design solutions, thus ensuring that we field the best grand prix cars we possibly can. In no small part Siemens has been a key contributor to our success in recent years, and the eight world championships we have achieved,” states Christian Horner, Team Principal, Infiniti Red Bull Racing.

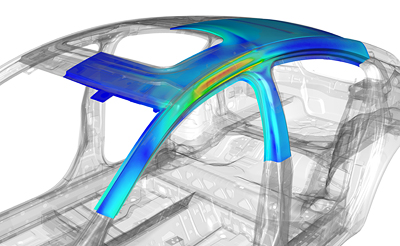

Later modifications can, of course, also be made quickly. To adapt the racecar to individual track conditions, developers can simulate a wide range of variants on the computer in order to find the ideal configuration. Both in the factory and at the track, engineers have access to all the design data they need to continuously monitor the results of changes to the vehicle.

Siemens PLM Software, a Business Unit of the company’s Industry Automation Division, is a leading global supplier of product lifecycle management (PLM) software and related services, with seven million licensed users and more than 71,000 customers around the world. Its industry software offerings provide Siemens with a platform that can transform companies in a wide variety of industries into digital enterprises.

The platform makes possible the full digital imaging and digital processing of every step in the product creation process. Today, industry software from Siemens is used for everything from adapting the front wings of Formula One racecars to particular track conditions and optimizing the complete car-making process to seamlessly monitoring every component in electronics manufacturing.

Siemens industry software enables companies to get products to the market faster, tailor offerings to individual customer requirements more precisely than ever before and continuously improve productivity and efficiency. With its industry software, Siemens is setting the pace in the digitization of manufacturing and thus enhancing quality and reliability.