The German company mbo Osswald is a leading manufacturer of mechanical linking elements with over 55 years of experience. 70 employees produce more than 12,000 standard parts at the site in southern Germany (Kuelsheim-Steinbach) and specialize in the production of custom drawing parts according to customer requirements.

We discuss with Lothar Winkler, Head of Sales & Marketing mbo Osswald, the strengths of the company, its business strategies and the role Italy plays in the international market. You will also learn more about the latest developments and successful applications of their products.

What are the strengths of your company in terms of product technology and solutions?

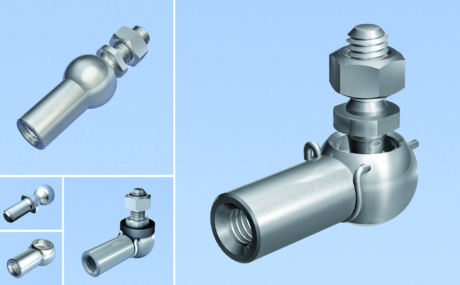

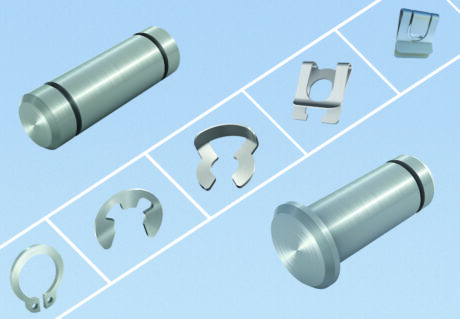

In 1967, everything started with the production of bolts according to standards. Over the years, mbo Osswald has evolved into a leading manufacturer of mechanical linking elements such as clevises, clevis joints, bolts, pins, angle joints, retainers, rod ends, and machine elements. The company offers a wide range of more than 12,000 standard parts and develops individual components together with customers. By using innovative manufacturing processes, automation, and software solutions, quality standards are continuously improved. Today, we are a manufacturer of standard parts, a contract manufacturer for precision turned parts, and a development partner for complex joint combinations.

How is your sales and logistics network organized?

mbo Osswald has a very large warehouse for standard parts, which enables flexible and reliable worldwide delivery of the highest quality. All customers can contact us directly and place orders. Both end customers and traders are supplied. Our employees have extensive experience in exports and can implement individual customer requests.

What are your main industrial reference sectors and which world regions represent your markets?

The company supplies a wide range of industries, from the toy industry to the automotive industry. Their largest share is in general mechanical engineering, with the German domestic market being the strongest.

What role does Italy play in your business strategies and what are the typical customers in our country?

mbo Osswald operates worldwide, with the majority of exported goods going to Europe. Traditionally, Italy, with its well-established manufacturing industry, is a strong partner and therefore plays a very important role for us. In particular, mechanical engineering, automation technology, and trade appreciate our products and services.

Can you name some new products that your company will focus on in the coming months, and what are their main features?

In addition to manufacturing, we have invested a lot in process optimization and expanding digital services in recent years. We recently revamped our webshop and equipped it with innovative features such as transparent price-quantity structure, delivery time display, tracking function, filter functions, and a bolt configurator. We will continue to expand these services. We rely on seamless transparency and offer the user maximum flexibility.

Can you give us an example of a particularly successful application of your products?

Clevises from mbo Osswald are preferably used in applications where linear force transmission occurs. They are almost exclusively used as clevis joints. A significant advantage is the simple and almost maintenance-free application. In addition, the extensive modular system convinces with a wide range of application possibilities. The force transmission takes place as a pivot joint with exactly one degree of freedom. Often, the clevis joint is also used for play compensation. Due to their robustness, clevises made of stainless steel are very successfully used in construction machinery.

How do you define your company’s performance in this particularly complex time for the world economy?

mbo Osswald constantly works to improve its performance in the current world economy and adapt to challenges such as the energy crisis, raw material shortages, and trade difficulties. Through forward-looking planning, optimized and very lean processes, we are able to react flexibly at any time. In particular, due to the high expertise of our employees, we can also implement special customer requests. As a manufacturer of mechanical connection elements and precision turned parts, we are only a small component in the supply chain, yet essential to prevent the supply chain from breaking. The innovative strength and flexibility of mbo Osswald enable us to successfully meet these challenges.

What strategies do you implement to address the energy crisis, raw material shortages, and trade difficulties in many parts of the world?

mbo Osswald relies on various strategies to meet current challenges. These include the use of the best manufacturing technology and high automation, a high level of delivery capability, support through intelligent software, collaboration with customers, and the development of customer-specific solutions.

Are there any special innovations that will shape the company’s path in this new year?

An important innovation this year is the revision of the customer portal in the webshop, which is now more user-friendly and offers new functions and services such as order tracking, contract documents, prices and delivery times, various configurators, and 3D models. Further features will follow to offer customers even more options for more efficient work.

More information can be found at www.mbo-osswald.de