Zani has chosen the experience of Bonesi Pneumatik to develop high performances pneumatik cylinders necessary for a new model of mechanical press.

Zany S.p.A. Metal Forming Machines is an Italian company that since 1960 has been developing and designing presses for cold sheet metal forming, with use in various fields: automotive, appliances, electronics, furniture and renewable energies. Located in Turate, in province of Como, not far from the Italian-Swiss border, it is managed by the family Zaffaroni, that now has turned into the third generation.

Zani has become a worldwide reference point in the market thanks to the high technology content of its machines and to the constant research of advanced solutions to improve the quality and the performances of the production. The organisational and designing know-how allow the company to respond with dynamism and flexibility to the new needs of the market, by keeping perfectly in mind that every customer is unique. For this reason, all the Zani presses, grouped in four families, are developed and designed according the specifications of the customer.

- Power Master: eccentric presses, with capacity up to 630 Ton, stroke 400 mm and bolster up to 4000 mm;

- Motion Master: jointed levers presses, with capacity up to 2500 t, stroke 800 mm and bolster up to

7000 mm;

- Servo Master: servo presses, with capacity up to 3200 t, stroke 800 mm and bolster up to 7000 mm;

equipped with one or more torque motors, direct drive to kinematics chain, without flywheel and

clutch, this kind of machines can reproduce any motion law;

- Hipro Master: fast presses with strokes up to 300 spm/min, capacity up to 300 t, stroke 100 mm and

plate up to 2000 mm.

The family Motion Master

The press of the family Motion Master, we are going to consider here, is one of the products with greatest success in the Zani portfolio because, such press guarantees a very high productivity and, at the same time, an absolute reliability thanks to the Link Motion kinematic specifically developed for this application.

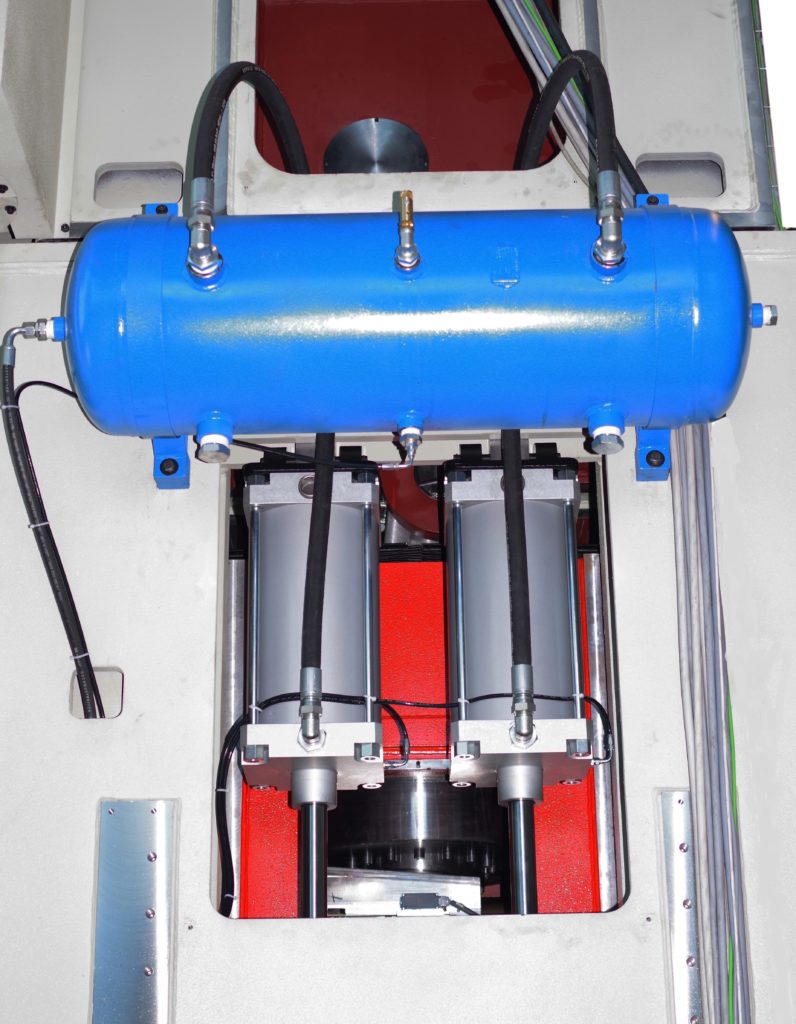

In fact, the motion is transmitted to the slide by a combination of levers, which dimensions, positions and angles have been studied to obtain the best performances requested by the customer. Such principle allows to obtain high-quality forming processes like cutting, coining and drawing with a remarkable reduction of noise during the working cycle. Moreover, this machine is particularly stiff with consequent advantage in the accuracy, reliability and duration of the die. In particular, this is the third machine realized by Zani for a well-known Swiss company that produces components in field of the fixing devices and of the assembling equipments in various areas from furniture to aeronautics. The press can reach a maximum speed of 80 strokes/min and it is equipped with a system of mechanical ejectors disposed in three lines controlled by two cams specifically designed. The slide is guided by a system of recycling of rollers that guarantees very high precision on the parallelism and on the perpendicularity of the motion. The press will produce aluminium discs initially extruded and then coined. Thanks to a transfer for the feeding of the pieces on the plate, the system can reach a productivity up to 240 pcs/min. The specific work conditions, connected to the mid-length slide stroke and to a high pitch, combined to the law of the motion of the kinematic with a slowing down in the proximity of the contact with the material and consequent acceleration during the upwards movement, shows that the linear speed of the slide can reach even values near to 1.5 m/s. Therefore, also the pneumatic cylinders, named balancing cylinders, necessary to balance the weight of the slide and to reduce the clearance during the phase of stamping, keeping connecting rods, levers and pins constantly under contact in order to avoid impacts, must be in the condition to carry out their work at the same high speed and to guarantee an absolute time-reliability.

The engagement of Bonesi Pneumatik

Therefore, the technical department of Zani has involved Bonesi Pneumatik for the realization of pneumatic cylinders with high performances that shouldn’t have modified the structure of the machine and its dimensions by using cylinders according ISO 15552 standards. Bonesi Pneumatik, thanks to his experience in the area of mechanical presses acquired during many years of activity, has developed special cylinders useful for the balancing at high speed of about 10 tons mass. Four cylinders bore 250 mm with stroke of 380 mm are used, working with dry air not lubricated at a pressure between 4 and 6 bars coming from the air tanks. They have caps in machined aluminium with increased air ports, tube in grounded steel and internally chromium plated, piston rod with seals in PTFE bronze loaded and it is used a lubricant grease with high performances and long life. These are the main technical features that allow these cylinders to work in difficult conditions. The close cooperation between the technical department of Zani and the technical/commercial department of Bonesi Pneumatik has allowed to develop and realize the press in short times, giving a technical support based on the experience acquired during years of activity in the area of pneumatic actuators, standard and special, in the various fields of applications.