From 10 millimetres to three metres. They are the minimum and maximum sizes of the components Ceba Ingranaggi has produced for half century for its customers worldwide, implementing either mass productions or the single tailored part.

Flexibility, optimization of mechanical processes, care of quality and of customer satisfaction: they are the strategic factors that have characterized the evolution of the Italian company Ceba Ingranaggi that precisely this year celebrates its first 50 years of activity. The company is specialized in the manufacturing of transmission organs of all kinds and can boast customers worldwide, it achieves a turnover of almost 10 million Euros, almost 40% of them coming from exports.

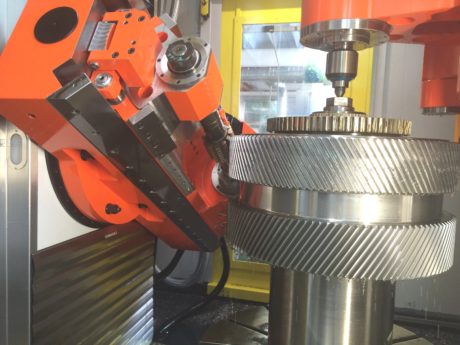

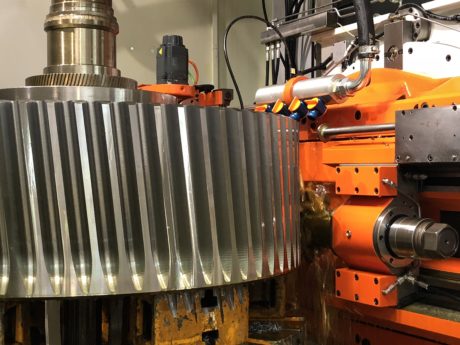

The company, today managed by Loretta and Fabrizio, sons of Giovanni Cesana, one of the founders, manufactures a broad variety of components: in its catalogue, Ceba includes numerous typologies of gears with minimum and maximum diameters of 10 mm and 3 metres respectively. The list is headed by those with straight and helical teeth, that is to say the standard cylindrical gears that absorb as much as 90% of human resources’ lavished energies, followed then – with more or less the same quantity – by spiral bevel gears, Gleason straight conical ones, chained gears, rounded gears and internal toothed gears. The manufacturing array encompasses also toothed pulleys, worm screws, grooved shafts, straight and helical racks, ground worm screws and so on. Moreover, the Brianza company implements tailored solutions, starting from the job order upon customer’s design to the finished product, ready for assembly. Such alloyed-steel offer particularly addresses the sector of sheet metal working machines, rolling mills, cardboard machines and many others.

One of Ceba’s highlights is the capability of offering both mass-productions and the single tailored component to customers: this enables the Brianza company to implement every year hundreds of different gears to meet specific applicative requirements, for instance creating teeth with different sides. The other element that has characterized the evolution and the growth of the company is the attention to investments: every year the company’s management lavishes the economic resources gained in the purchase of new machines and state-of-the-art technologies.

“Made in Italy” gears for half century

1969. Ceba Ingranaggi S.r.l was born fifty years ago from the entrepreneurship of Giovanni Cesana who, after gaining a long experience in the technical office of a firm producing presses and shears, sets up the company with a member. Cesana guessed the potentialities of a specific sector, transmission gears, and starts a first production of straight and helical cylindrical gears and worm screw machining. The first gear cutting machines were second-hand and overhauled.

1972. After the employment of three workers, Ceba Ingranaggi develops its workshop, extending the surface to 350 m2. Besides relying on new spaces, the company enhances its resources, meant both as employees and as machine fleet, and increments the production typology with teeth up to 2,000 mm of diameter, rounded gears and racks. The company first approaches the evolving grinding in this period.

1980. Through unceasing investments and the decision of supplying special high-quality machining instead of mass-productions, the company goes on growing and expanding. In these years, Ceba engages 17 workers, the workshop is enlarged by 800 m2 and some new machines are bought, a large gear cutting machine and some grinding machines, which allow processing up to 3,000 mm in diameter.

1996. It is the year of the turning point. Ceba Ingranaggi is transformed into Ltd company and starts the works for the construction of new buildings taking up 3,200 m2 where it is still headquartered, in via Tiziano 8 and 11, at Carate Brianza. It can now rely on a consolidated reference of customers, to which it supplies machining as supplier and/or subcontractor. Besides, it has also consolidated a group of suppliers that, for mechanical machining and heat treatments, collaborate with CEBA with quality and precision of supplied machining and processes. In 2001, the company reaches also the important goal of the certification of its quality system, as guarantee of accurate machining and controls executed.

2006. To give its customers more and more complete and competitive services with cutting-edge technologies, Ceba Ingranaggi has been continuously enriched with modern NC machines of German, Swiss and Italian manufacture, completing itself with state-of-the-art machinery based on technology 4.0. Just in the 2016 – 2017 biennium, the production division is integrated with 6 new machines, two grinding machines and four new CNC gear hobbing machines with technology 4.0. In general, Ceba can now produce a large variety of parts, from simple to most complex ones, including Klingelnberg conical spiral gears, made with specific CNC gear cutting machines.

2019. 50 years after its foundation, Ceba Ingranaggi is now supported by its direct labour force composed by 32 workers and by some external mechanical workshops employing other 20 people. The second generation of Cesana family has succeeded in continuing the dream of the founder Giovanni, upgrading the company according to the requirements of the market, by now become global, without losing sight of the typical human and social values of its business origins. The management is everyday committed to using machines and personnel with machining and control procedures, programmes and documents according to the rules established by the internal quality system in compliance with UNI EN ISO 9001:2015, to protect its customers’ interest.