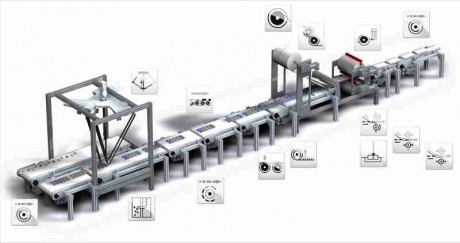

Endeavouring to do justice to the manifold market requirements for greater flexibility and a shorter time-to-market while, at the same time, striving to keep engineering times and costs under control, mechanical engineering companies are assigning more and more importance to the modularisation of machines. This approach is being supported by Lenze, the specialist in Motion Centric Automation, with its range of products, systems and services. Lenze has continually expanded its range in recent years and has invested intensively in its portfolio of products and services – for example, in the development of standardised application software. With Lenze Fast, for instance, Lenze supports mechanical engineering companies in creating modular control software more quickly and easily.

Today, saving time in the engineering process is a decisive factor for success. Lenze Fast makes it possible for programmers to do up to 80 per cent of their software engineering work for standardised machine modules extremely quickly and reliably. Due to the (re)use of ready-made and tested function modules and technology modules, costs can be lowered, errors reduced and valuable time gained for the implementation, testing and commissioning of specialised machine characteristics that allow the mechanical engineering companies to leverage significant benefits for their customers.

Lenze will also be showcasing some innovative drive solutions that are especially efficient thanks to mechatronic integration. These are based on the new finely graduated g500 gearbox series, which has been specially developed so that rotational motor speed can be converted into torque as intelligently and precisely as possible. The high degree of efficiency offered by the combination of Lenze Smart Motor and g500 gearbox series ensures considerable advantages when it comes to energy efficiency. What’s more, it is possible to cover an extensive bandwidth of applications with just a single mechatronic drive solution. As a result, the variety of different drives can be reduced by up to 70 per cent. Thanks to outstanding energy efficiency and a long service life of the solutions, customers achieve greater productivity while enjoying the considerable advantages of maximum machine reliability.