Mattei Group presents the RVR range of compressors. Compact design, reduced footprint, and superior reliability: advanced technological solutions for the rail industry

Mattei Group presents the RVR range: rotary vane compressors specifically designed for the Rail sector.

The sector is one of the most interesting markets for the company from Vimodrone, specialised in the production of rotary vane compressors, which for years has had prestigious collaborations with the main rolling stock manufacturers in Italy and Europe, developing important partnerships, as well as pilot projects and partnerships between the US division, Mattei USA, and international giants such as the Alstom group for divisions such as the metro and People Mover systems.

The RVR range offers compressors used on board railway vehicles, such as high-speed or regional trains, passenger or freight trains, traditional, hybrid and shunting locomotives, and are used in different applications ranging from: door activation, sandboxes, pantograph handling, braking and suspension systems.

They are also widely used in industry servicing infrastructure such as depots and maintenance areas.

A compact, quiet, and efficient compressor

RVR compressors are compact, quiet, and efficient, and provide consistent performance, reliability, functionality, and ease of use. Thanks to the rotary vane technology they also offer high performance, energy savings and a longer product life cycle. For example, its pumping unit has a guaranteed operation of more than 100,000 hours, without having to be overhauled.

A significant plus of Mattei’s RVR compressor range is that their quality standards are IRIS-certified, an international certification promoted by UNIFE, the Association of the European Rail Supply Industry, which aims to assess the quality of suppliers of rolling stock and related equipment.

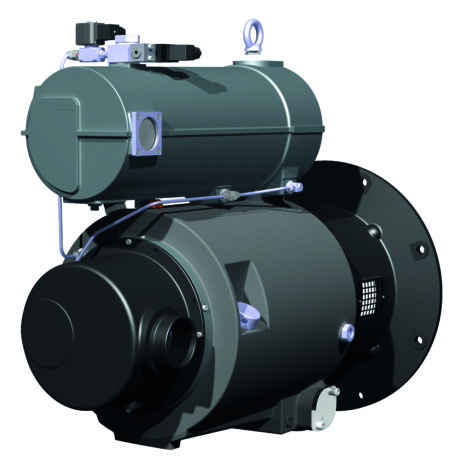

Another advantage of the range is its flexibility: the RVR compressors can be integrated into equipment with a compressed air generation and treatment system (AGTU), complete with pumping unit, motor and dryer, oil separator, enhanced inlet filtration, and compressed air treatment system equipped with filters, dryer and respective control devices; or they can also be used stand-alone for retrofitting in existing compressor applications, integrating with the motor.

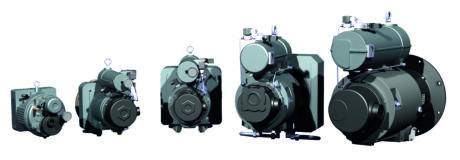

Five different models

The RVR series offers five different models, each available in different configurations.

RVR01, specifically designed to meet the needs of trams and light rail vehicles, producing compressed air in the range 0.10 – 0.48 m3/min.

RVR02, designed and manufactured to meet the specific needs of light rail and metro vehicles, producing compressed air in the range 0.30 – 1.58 m3/min.

RVR03, created to meet the compressed air requirements of electric and diesel vehicles, regional trains, high-speed trains and railway maintenance vehicles, with compressed air flow rates from 0.79 to 3.30 m3/min.

RVR04, designed and manufactured for electric and diesel railway vehicles and track maintenance vehicles, with compressed air capacities from 1.56 to 5.22 m3/min. Each of these compressor types is available as a stand-alone compressor, with an integrated air cooling system, coupled to an electric or hydraulic motor.

The RVR05 is specifically designed to meet the needs of heavy Class 1 locomotives. It is the most powerful with air deliveries from 2.50 to 9.69 m3/min.

It is available either as a stand-alone compressor unit or coupled to an electric or hydraulic motor.

Research & Development at Mattei never stops; and despite the high quality levels already achieved, the next challenge will be to make the RVR series even more sustainable by developing a durable, highly biodegradable, non-toxic lubricant specifically for rail applications.