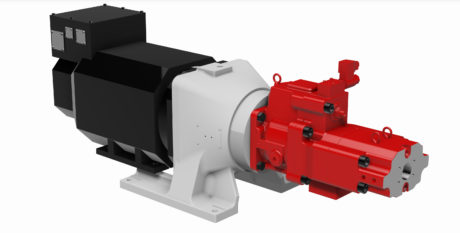

Thanks to a recent collaboration with Kawasaki Precision Machinery, Interfluid is official distributor of Eco Servo, electro-hydraulic hybrid system.

The electro-hydraulic hybrid system Eco Servo Kawasaki, distributed by Interfluid, delivers energy savings and reduced noise by controlling the speed of the hydraulic pump, the pressure source of the hydraulic-drive system, in response to required power.

Eco Servo is applicable to both open and closed circuits, employing not only the standard pump intended for open circuits but also special pumps (with suction valve) intended for reversible high-pressure and closed circuits. Through the use of a variable displacement pump that is capable of two displacement settings, the necessary drive torque can be lower and the necessary motor capacity can be smaller.

To best cope with an intended system, Kawasaki Eco Servo can be driven by either a servo motor, that boasts good control performance, or an inverter motor that excels in cost-performance.

The introduction of the housing to restrain the propagation of pump vibration allows to reduce the noise. The system is also made more compact and lighter by a reduction in heat value and the simple configuration contributes to improved maintainability.

Kawasaki Eco Servo employs the Kawasaki piston pump K3VL Eco Servo Series, distributed by Interfluid, product that boasts the good reputation for their high-pressure rating, high capacity and high efficiency. Speed control by K3VL Kawasaki high-efficiency pump, achieves 40% energy savings as compared with the existing system.

Eco Servo Kawasaki (available displacements: 22, 45, 80, 112 and 140) allows to reach pressure ratings of 320 bar rated – 350 bar max, max. speed: 2000 min-1 and max. discharge: 280 l/min (pump displacement: 140 cm3).