Electroforce, the new servo-actuators with high force density and high protection degree by Setec Group

Electroforce is the new range of servo-actuators designed and implemented by Setec Group, a benchmark in mechatronics, to meet first the many different needs coming from the marine sector and then also available for a perfect use in the whole industrial world.

The concept

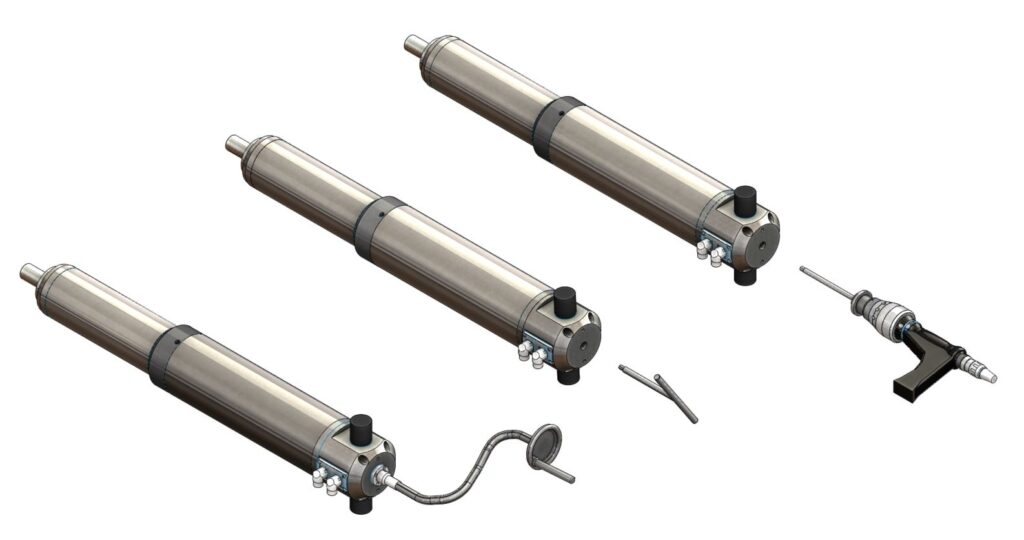

The concept developed by the Group, headquartered at Borgaro Torinese (Turin, Italy), was to create an actuator with a round circular shape very similar to an hydraulic cylinder, with a beautiful design, hosting in its interior a brushless servomotor equipped with brake, a precision planetary gearbox, the bearing unit (i.e. the group of thrust bearings that releases the axial load from the transmission) and a system of rotary screw and translating nut, the latter connected with the rod.

Available in two versions

Therefore, Electroforce is configured as an electro-cylinder under all respects, made available in two versions, with trapezoidal screw and with ballscrew, to meet all the most frequent technical requirements.

As an option, both versions can be anyway provided with safety nut that starts working when the main nut screw is worn out.

Advantages

The new range, since electromechanical ones, includes among its advantages not to be energy-eater (because the real consumption occurs only during motion), to be very silent when in operation, compared to other technologies, to be simple and fast to install and to commission, to be easy to synchronize, to be self-locking and not polluting the environment with oil.

Three available sizes, with mirror-polished finish, too

Thanks to its genesis, Electroforce has been implemented with some devices, on both standing still and moving parts (the rod) that are more typical of the marine industry, to assure, for instance, at least an IP66 protection degree. For the same reason, in the rear part of the actuator, Setec team has integrated also a standard coupling device, to allow a manual emergency actuation in case of fault of electrical power.

As a standard, they are made of carbon steel with “marine” painting cycle, with rod and connection thread in Aisi 316L stainless steel, but they are also available in full Aisi 316L stainless steel version with mirror-polished finishing.

More in detail, three standard sizes are provided, E100, E140 and E200, available in the “T” version with trapezoidal screw or “S” with re-circulating ball screw.

- E100-T, Ø 100 mm, maximum nominal force 23,000 N

- E100-S, Ø 100 mm, maximum nominal force 28,000 N

Marine and food&beverage are only some of the many sectors with the highest application potential, together with the many field of packaging and of the general machine maker industry.

- E140-T, Ø 140 mm, maximum nominal force 34,000 N

- E140-S, Ø 140 mm, maximum nominal force 65,000 N

- E200-T, Ø 200 mm, maximum nominal force 56,000 N

- E200-S, Ø 200 mm, maximum nominal force 140,000 N

Data highlight that the two Electroforce actuators, opportunely coupled, synchronized and controlled, can generate remarkable forces, once used together.

Marine and food&beverage are only some of the sectors with the highest applicative potential, in addition to the diversified field of packaging and general industry.

In any case, due to their concept and implementation, these servo-actuators find their natural application wherever high protection degrees are demanded and there is the compactness operational requirement in at least two of the three dimensions.

Moreover, in industrial applications where the aesthetical impact has a great importance.

(by Gianandrea Mazzola)