Great care and attention in manufacturING, together with innovative design solutions, make the actuators designed and developed by the Setec group an ideal solution for several marine applications.

Setec Group has been designing, developing and producing for more than 40 years of wide range of industrial electromechanical linear actuators for all industrial sectors. Many thousands of standard and special actuators have been produced and installed in almost all kind of applications, including the marine sector. Such is the case of the Electromast series of telescopic mechanical linear actuators and the servoactuator Seard series with added remote drive system; both patented.

These components represent the natural evolution towards the high added value pleasure vessel sector, which is rapidly being transformed by the use of new electromechanical and electronic technologies. This guarantees not only greater energy efficiency and very compact dimensions, but also quiet operation and less environmental impact.

«A range of products,» says general manager Fabio Seminatore, «that benefits from all the know-how and experience in design, production and applications built up by a company in all the main international markets and in all the most important industrial sectors of machinery construction.»

The same great care and attention that goes into making the motion components for the automation market is put in place to get new products that are then an ideal solution for marine applications.

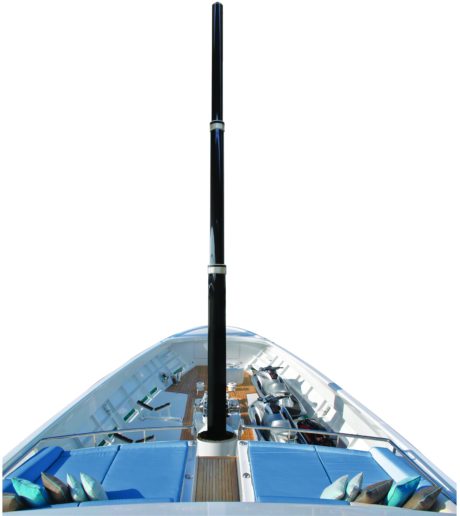

Performance and aesthetics for hoisting navigation and at-anchor lights at the bow

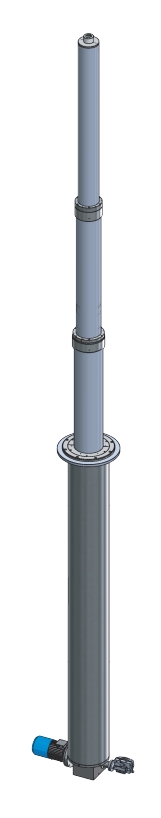

In detail, the Electromast actuator is a purely electromechanical telescopic cylinder with three sliding elements in carbon fibre (activated by transmission elements in special light treated alloy) designed to hoist navigation and at-anchor lights at the bow of ships longer than 50 m.

This innovative range offers several distinct and different advantages.

«First of all,» says Seminatore, «it is a completely electromechanical system and thus it doesn’t need any hydraulic element. This means it has no dedicated powerpack (weight and footprint) and eliminates the use of hundreds of litres of oil for the lengthy extension required. A single component with cylindrical electromechanical axial development with a double effect that avoids the presence of any oil leakage that could end up in lockers or even in the sea. Then there are no serious risks of hydraulic pipes under pressure bursting and causing risks of fire and significant pollution.»

It is designed to be mechanically non-reversible, that is, once it is in any position, it needs no electric power (so it only consumes a little energy when it is activated), and inside it is completely hollow. As a result of it the electric cables powering the lights can pass through the mast and so are completely protected and not on view, and are gathered up by a device at the foot of the mast. Quiet operation and aesthetics are further strong points.

«This actuator,» says Seminatore, «thanks to a transmission system with intrinsically very low noise emission, is overall particularly quiet. In addition, it comes out of the floor showing only the three sliding elements in polished carbon fibre with visible weave and the polished flanges in stainless steel.»

The mechanical activation system inside is bi-directional, it activates positively in both senses: extending the mast and retracting it. So, if there are deposits of salt that tend to block retraction, the internal transmission pulls the three sliding elements towards the inside, overcoming the obstacle. Installation costs are also reduced. The actuator has an upper flange close to where the sliding elements emerge, which allows it to be fixed rigidly to the structure of the vessel.

«The yard,» says Seminatore, «just has to hold it, gripping the external cylinder. Once the adjustable electromechanical stop points have been set up, to complete the installation you just need to connect the electric cables of the three phase motor of the actuator and the stop points.»

Finally, as mentioned, since there is no oil under pressure there are no risks of leaks or fires due to pipe breakage.

Quiet and efficient opening and closing

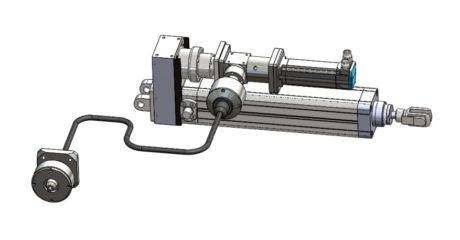

Created for the controlled linear motion of systems for opening and closing doors and hatches, tender hoist extensions and helms (to mention only the main applications in the marine sector), the Seard actuator is also a purely electromechanical cylinder. This means it shares with the Electromast series described above certain features such as the absence of hydraulic activation, compactness, quiet operation, low environmental impact, greater safety and high energy efficiency.

«We are speaking of a range of actuators,» says Seminatore, «that permit remote activation. They have a remote drive system, in case the main motor of the actuator does not work (for example In case of electrical black-out) which, by the use a mechanical unit with a special flexible cable or an auxiliary electric motor,allows to move it anyway.»

Installation is very rapid for this series too and involves no particular additional costs: the actuator has just electric cables that must be connected to the control panel, nothing more.

The standard range offers both axial and parallel configurations. In both cases there are four sizes available (80, 80 HL, 100 HL and 100 XL), with maximum power, according to the model choosen, from a minimum of 12,500N to a maximum of 55,560 N. The top speed is 300 mm/s with standard ranges from 100 to 700 mm.

«Maximum power with cable remote control,» says Seminatore, «ranges from 12,500 Newton for the model 80 to 15,000 Newton for the other type 8 versions. It is from 25,000 N for the 80 HL model to 30,000 Newton for the 100 HL and 100 XL configurations.»

The Setec Group in brief

With headquarters in Turin, the Setec Group has five establishments strategically located in Italy and three warehouses that continually exchange supplies to optimise local availability. This targeted logistics ensures rapid deliveries nationally and internationally. The modern and prestige headquarters in Borgaro, in the northern part of the city, occupies an area of 10,000 m², 6500m2 of them covered, which houses the general management of the group, engineering, production, test laboratories, the sophisticated measurement room, the central warehouses and the general administrative offices. A dynamic and flexible structure, with more than 40 years of activity, that can offer a global service in mechatronic automation. Screw jacks, electromechanical linear actuators, mono and multiaxis servo systems complete with software, rotary actuators, linear units with belt all screw, industrial brakes and clutches, linear guideways, ball screws, precision planetary and angle gearboxes and servomotors are the heart of the technological offer. The Setec Group, thanks to the vast experience it has built up in the motion control field applied to the most widespread industrial sectors, can supply oems with all the know-how needed for engineering analysis to produce innovative machinery that respects the environment and is increasingly high-performance