In its thirtieth year of activity, Servomech reconfirms its bent for innovation by releasing on the market the advanced line of servo-actuators: the New Series SAM.

Know how, in-house manufacturing cycle and quality are the boosts that since 1989 have characterized Servomech Group, reference international player in the design of solutions for linear motion. Servomech celebrates its 30 years of activity with a further innovation enhancement as, with the new New Series Sam, they complete the range of electromechanical servo-actuators Linearmech, Group’s brand dedicated to automation and mechatronics, as alternative to pneumatic cylinders, too. Compared to standard systems, Linearmech servo-actuators adopt fully innovative solutions with regard to traditional electromechanical cylinders. They match at best the demands for ever-rising performances and more productivity of plants with competitive industrial costs. They are ideal to replace pneumatic cylinders in applications with high operation dynamics, high precision, positioning repeatability and reliability in time.

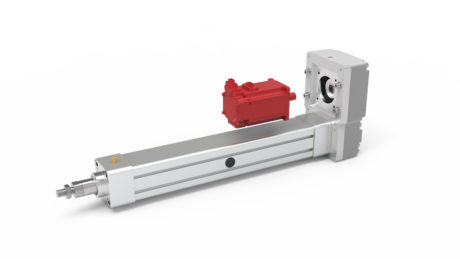

The new Series SAM, linear servo-actuators with customized motor interface, today allows combining high-performance mechanics by Servomech with the servomotors by the major brands on trade. Nowadays available in the configuration with parallel and in-line assembly. Seven different standard sizes are available, with linear speeds up to 1,500 mm/s and feasible peak forces up to 4,600 daN.

All servo-actuators are provided with re-circulating ball screws in-house manufactured by Servomech (different precision classes for all applicative requirements) and with a broad range of fixing elements according to the standard of ISO 15552 pneumatic cylinders, for a full simple interchangeability with existing pneumatic cylinders. In addition to the new SAM series, complete configurations of Servomech servomotor, with in-line or parallel assembly, are available.

The total control of the whole manufacturing process, the fully modular construction and the different structural typologies allow Servomech to grant utmost use flexibility to customers, even with customized solutions.

Continuous innovation

The propensity for innovation characterizes also other made in Servomech implementations, like the range of high-performance electromechanical cylinders. Compared to hydraulic executions, it is more efficient, with lower energy consumptions. This result allows installing smaller powers and consuming energy only when in operation. Another peculiarity concerns the better control of position/speed/ force.

Worth highlighting also the positioning precision, the high constant repeatability in time and the better safety and reliability. These cylinders, also customized and available in various assembly configurations for a total interchangeability with existing hydraulic cylinders, assure lower installation and maintenance costs, too.

Finally, not less important also mechanical jacks with re-circulating ball screws, patented technological evolution overcoming the applicative limits of those with trapezoidal screw, fully studied and manufactured by Servomech, for a kind of mechanics that looks at the future.