Saip is an Italian company specialized in the production of hydropneumatic accumulators and pulsation dampers, in the diaphragm, piston, bladder and bellows versions.

Hydropneumatic accumulators are pressure vessels that use the different fluid compressibility for their operation. The incompressible liquids exploit the gas compressibility to allow the accumulation of fluidic energy under pressure. The upper part of the accumulator contains in fact pressurized gas (nitrogen), while the lower part, (diaphragm, piston with seals, bladder or bellows), is connected with the hydraulic plant; when the plant pressure exceeds the gas pressure value, the liquid enters the accumulator body compressing the gas, while when the plant pressure drops, the gas pressure makes the accumulated pressure liquid flow towards the plant.

Forty years keeping pace with times

The industrial expertise, gained in 40 years of experience, has allowed Saip to develop – besides the more and more reliable catalogue products – customized solutions to offer the best technical application to its customers.

In the productive headquarters at Opera, in the outskirts of Milan, connected with the motorway network and close to the international and intercontinental airports, design and production logistic equipment undergoes constant technological upgrading to maintain the high quality standards, to achieve an excellent quality-price ratio with shorter and shorter delivery terms.

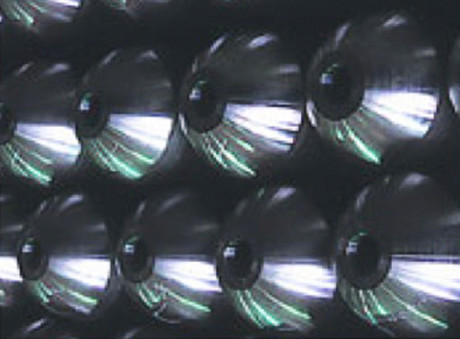

The latest, in order of time, is a fully automated plant for the production of maintenance-free diaphragm accumulators (average production capacity: 1000 accumulators/day). These accumulators are produced in the nitrogen-rechargeable versions or with fixed factory pre-charge, not modifiable by the user, with standard or special liquid-side connections and internal separation diaphragm between the gas volume and the process liquid in various compound typologies, depending on the liquid used and/or the use conditions. They are constituted by two high-strength steel caps, electron-beam welded, with the diaphragm that cannot be replaced inside, since specifically designed for big production batches and low-cost applications: with this production system, it is more convenient and practical to replace the entire accumulator instead of carrying out its maintenance.

Main application sectors

The main use sectors are the industrial one of small or mini hydraulic power plants, of machine tools, the mobile and agricultural sector. Compared to other versions of accumulators, this typology (WA) has a higher efficiency (energy/mass content), due to the hemispheric shape of the body. These accumulators are manufactured in the capacities from 0.05 litres to 4 litres, with maximum working pressures of 100,140,210, 250,300 and 350 bars, in carbon steel and stainless steel versions.

To exploit at best the investment made to produce the said accumulators and to provide the market with concrete solutions, a part of the plant was modified to manufacture small-size piston accumulators, too (from 0.1 to 6 litres), in the not repairable version or in the model dismountable from one side only. This new PAW series completes the already renowned typology of standard piston accumulators (PAM) with bottoms/nuts screwed and capacities from 0.4 to 1000 litres and maximum pressures of 1035 bars.

Another typology of accumulators in which Saip is investing two different production technologies are low- and high-pressure bladder accumulators, drawn from tube with hot spinning operation, for weld-free production, the other is instead the production of big-capacity welded accumulators.

Low- and high-pressure bladder accumulators

Low- pressure bladder accumulators type SL, are produced up to the capacity of 55 litres and they differ from the high-pressure line type SI mainly for the liquid valve type mounted, besides naturally the various body thicknesses. The first have the liquid valve with drilled plate, while the second have the liquid mushroom valve. SI-type bladder accumulators are produced for pressures of 210 bars, 360 bars and 690 bars.

BA-type bladder accumulators are generally composed by bent sheet metal and by two welded bombed bottoms, suitable for working pressures up to 30 bars and produced with max. 15,000-litre capacity.

The three typologies of bladder accumulators can be manufactured as listed below, depending on the customer’s requirements and/or the strength specifications of the accumulator:

– with carbon steel

– with high-strength alloyed steel, with suitable heat treatments for granting the design specifications

– with AISI 316L stainless steel

– with duplex or super duplex steel.

All Saip accumulators are designed, manufactured, controlled and tested in compliance with the European Directive “Pressure Vessels” 97/23/CE and/or other regulations that are requested in order phase, according to reference specifications and/or depending on the installation Country of the accumulator. According to the directive in force, they use harmonized materials, with the characteristics and the requisites demanded by the reference regulation and/or the calculation code.

Other certifications:

- ASME U-STAMP for USA (National Board), Canada (CRN), South Africa, etc.

- ML (ex SQL) for China

- Australian Pressure Vessel standard AS1210-1997 for Australia

- CU-TR for Russia, Ukraine, Kazakhstan, etc. (ex Gost-R)

- Dossier RTN – Rostechnadzor for Russia, Ukraine, Kazakhstan, etc.

- DDP passport for Algeria, Tunisia, etc.