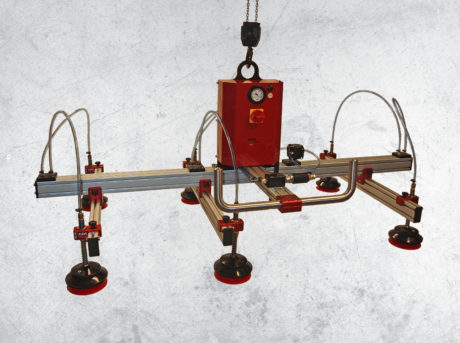

Ultra-flexible vacuum lifter for sheet metal and timber processing

FIPA entered into the lifting technology market in mid-2015. And now the specialist in gripper, vacuum and lifting technology based near Munich is really upping the ante: The company’s new Fipa Spider is a vacuum crossbeam that will set benchmarks on the market. Thanks to its lightweight aluminium structure, the Fipa Spider is extremely easy to handle. Its modular construction and extensive accessories mean that it can be customised. What’s more, the plug & play concept means that installation takes no time at all – making handling flat workpieces in sheet metal and timber processing child’s play. CEO Rainer Mehrer on the addition to the range: «As we have done with End-of-Arm-Tooling, we are positioning ourselves in this segment with a highly flexible product. Modularity for adaptation to suit customer needs is our core aim: The point at which special production begins for others has long been standard for us.»

The new vacuum crossbeam, also known as a vacuum lifter, comes in two designs: up to 250 kg and up to 500 kg. Alongside its lightweight properties, as well as modularity and rapid installation, the Fipa Spider offers further benefits that facilitate ergonomic working and an efficient material flow. When compared to classic hoists with slings, the vacuum lifter impresses with its uncomplicated workflow: attach the vacuum cup, activate the hand slide valve, then lift after the vacuum has built up – and that’s it. There’s no need for extensive training. Careful treatment is also important when lifting sensitive workpieces, e.g. when processing timber. At the same time, lifting solutions come into contact with wood shavings, splinters, resin and dust. The large selection of Fipa vacuum cups guarantees safe handling of panels and sheets without leakage issues. For sheet metal processing, for example, the company offers low-marking vacuum cups to ensure gentle handling before painting or gluing processes. Compared with other manual solutions, the Fipa Spider makes it considerably easier for the user to handle bend-resistant workpieces and increases working safety.

«Since entering the market in 2015, we have successfully gained a foothold on the market with our manual lifting equipment,” says Rainer Mehrer. Demographic change, worker shortages and increasing numbers of regulations relating to occupational safety are leading to growing demand for vacuum lifters. “With this in mind, we are swiftly expanding our portfolio in order to be able to help in a variety of scenarios.»

The tube lifter FIPALIFT achieves short cycle times, facilitates rapid, smooth working and can cope with a variety of workpieces. The Fipa Spider is designed for use on a chain hoist and, thanks to its great lifting force, can also lift weights of up to 500 kg. As there is no block dimension – unlike in the case of FIPALIFT – it can also be used in areas with a low ceiling height. «Our solution combines many benefits at a manageable acquisition cost and impresses with its low operating costs, thanks to low energy consumption.»