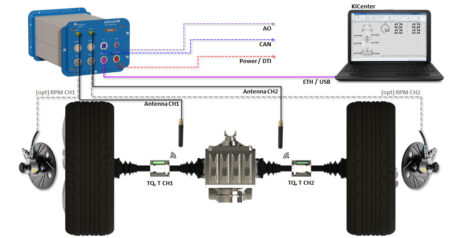

With the KiTorq DS, Kistler developed the first torque measuring system for automotive drive shafts that features wireless data transmission. The transmitter, which covers the strain gauge sensor, is attached to the shaft via adapter sleeves. This allows users to easily remove the unit to change and recharge the batteries or reuse the transmitter on another vehicle. The corresponding receiver unit can process input of two transmitters and receive the signal of the wheel pulse transducer of type CWPT from Kistler to directly measure wheel speed, acceleration and calculate power.

First wireless torque measuring solution for drive shafts

Especially in the development of electric vehicles, torque measurements on drive shafts become increasingly important since they enable engineers to better calculate the efficiency of the entire power train including recuperation. Kistler is now offering a new solution that makes these measurements significantly easier.

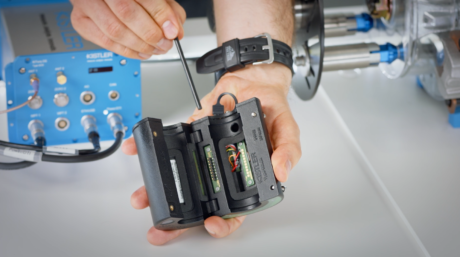

The new wireless torque measurement system consists of two transmitter units and a receiver unit. The unique design of the transmitter unit features two half-shells that close around the shaft. While the telemetry half-shell is sending the data to the onboard evaluation electronics, the other shell holds the replaceable and rechargeable battery.

Customized adapter enables reuse of transmitter unit

The unit is quickly installed and removed by attaching to an adapter sleeve on the shaft, which also means that it can be reused on other vehicles – making this solution more sustainable and cost-efficient than single use solutions that have to be fixed directly on the test object. The half-shells are available in six basic variants that cover the most common drive-shaft diameters of passenger cars, regardless of the drive concept. The adapter is tailored to the exact measurements of each shaft and ensures the optimal fit of the transmitter unit.

The system includes an automatic recognition of the drive shafts to be measured. Additionally, it can bridge a power supply interruption of up to 30 seconds and has a variety of digital data outputs such as CAN, DTI, and Ethernet. The space-saving receiver unit receives and processes torque and temperature signals from up to two transmitter units. In total, up to six transmitters can be used to measure torque on six shafts (e.g. two axles and propellershaft) simultaneously. To ensure optimal measuring results, Kistler also offers services such as strain gauge application and the calibration of the shafts.