Many installation sketches and technical drawings contain the remark “Adjust during assembly”. To ensure that this does not become a nerve-racking and time-consuming procedure, German supplier Georg Martin GmbH is now offering customer and application-friendly assorted mini assembly kits in its M-Tech P product line for efficient tolerance compensation when assembling components.

What the user gets is an individually compiled set of fine adjustment films precisely coordinated to fit every joint which can be used as required during assembly and maintenance work.

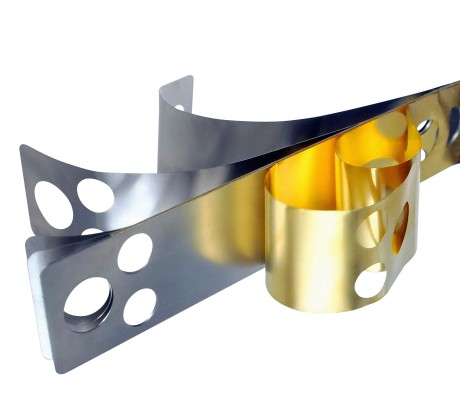

Users can choose here as desired between mini assembly kits with foils made of stainless steel, steel, NF metals or composite materials with individual thicknesses of 10 µm to several millimetres. Martin also allows the customer to choose more or less at will with regard to quantities, arrangement, sequence, shape and even the materials mix. There are also the mini assembly kits which come as “tear-off calendars” with perforations, edge-bonded or loosely bundled.

In the logistics of production, assembly and maintenance, the use of properly coordinated mini assembly kits from Martin can completely replace expensive mechanical compensation methods such as grinding.

Thanks to their easy handling (no need to peel them off) and high precision, the customized shim sets are simply ideal for the successful implementation of lean and economical assembly processes in sectors such as drive technology, mechanical engineering and automotive engineering.

If the use of mini assembly kits is taken into consideration during the development of a sub-assembly, all subsequent processes benefit too, from work preparation through production to repair and aftermarket service. As a further consequence, the expense, effort and personnel required for other business processes such as stock monitoring can also be reduced, as can investments in machinery.

Georg Martin at the following trade show: AIRTEC, the 10th international aerospace supply fair, 3 to 5 November 2015, Munich, Germany: Hall C3 Stand E65