The Italian company Gambini Meccanica Srl was founded in 1978 and it has specialized mainly in the production of transmission gears. It was born as an hand-crafted reality, while today it is a certified company (UNI EN ISO 9001/2008 related to Quality Management System and OHSAS 18001/2007 related to Occupational Health and Safety Management System), technologically advanced and structured with state-of-the-art and continuously updated production plants. Today, thanks to the production flexibility and to the industrial automation, Gambini Meccanica is able to realize products with high competitive prices in all over the world, both with standard features and with the most elaborate customizations.

The company has just moved to a new factory in Pesaro, which presents a surface of 7.000 square meters with an advanced logistics system. Moreover, it has opened a new German branch in Munich: Gambini Deutschland GmbH which offers high-quality and high-tech services.

The productive technologies employed in Gambini Meccanica are constantly certified and thanks to the great investment capacity and to a continuous technological innovation the company is able to produce products with the maximum accuracy.

Gambini Meccanica wants to be on the cutting edge not only in Italy, but also all over the world, by employing not only advanced computer systems, but also really accurate machines such as the Surface Induction Hardening Machine which is able to satisfy all market needs in racks and gears’ surface hardening.

Surface hardening increases the wear resistance and can be used to increase the strength of highly stressed components. The machine treats each work-piece individually and this means each and every work-piece is hardened to very precise specifications.

Gambini Meccanica can realize induction hardening in passed or tooth by tooth (both max length 3000 mm).

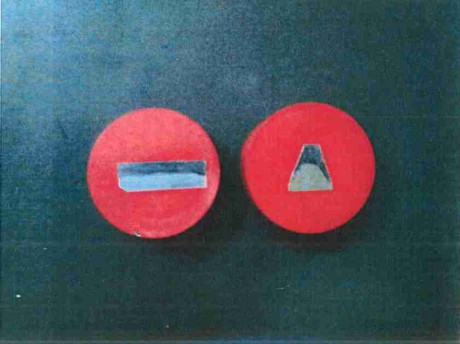

Thanks to the use of an high frequency machine, the company is able to realize induction hardening in passed until module 4 included; whereas, due to the use of a medium-high frequency machine (from M5-M10) or a low frequency machine (M10-M30), the company is able to realize induction hardening tooth by tooth which guarantees to reach a correct hardening line more suitable for the biggest modules’ applications.

In addition to this, Gambini Meccanica has also its own internal Quality Control Testing Area equipped with measuring instruments and composed by specialized technicians which test the treated parts according to the technical specifications required by the customer; the Testing Area also issues heat treatment certificates: paper certificates which report the hardness and its deepness.

The main benefits of induction hardening are the speed of execution and the possibility to perform both small batches and entire orders with absolutely the same results.

The activity of Gambini Meccanica consists in the production of every type of toothed pulleys, gears (from module 0.5 to module 30), toothed wheels, metric and modular racks (from module 0.5 to module 30), splined shafts, endless screws, trapezoidal screws, screws nuts, plate wheels, pinions, reduction gears, pneumatic pumps, endless screws reduction gears, speed gearboxes as per plan of the Customer and their assembly.

In order to collect more information about the activity of Gambini Meccanica, you are invited to visit the web site www.gambinimeccanica.it, so that you can also better understand its strength: Precision and Resistance … the perfect combination.