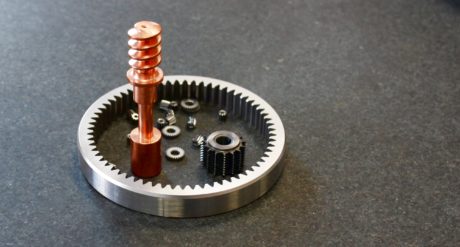

Specializing in the production of gears, microgears and automatic precision turnery, Anfabo can rely on its well-established experience which allows satisfying even the most demanding sectors.

Since its foundation in 1987 Anfabo, based in Saronno (Varese, Italy), has been aiming at constant technological updating which has become one of its strong points, as well as following the market developments with great attention. Such developments have led to continuous improvement in those processes that are the company’s specialization: production of gears, microgears, and automatic precision turnery. We are talking about activities which currently take place in the new plant in Caronno Pertusella, in the province of Varese, on an area of about 2,500 covered square meters.

«We faced an important investment – says Andrea Boeri, company owner together with his brother Fabrizio – which finds a proper collocation in substantial change and planning which has been carefully studied and in which we have strongly believed and still believe in, that is a plan for growth and expansion of our potential».

The new production unit has been developed according to specific needs, such as the identification of the different areas and the displacement of the departments; all with the express purpose of optimizing the process of product development and involved manufacturing, while including more details to be processed.

«An effort – says Andrea Boeri – which allows us to look to the future with the confidence of effectively meeting the various market needs.»

A market whose demands require ever higher quality, operational flexibility and fast response times. If one also adds the fundamental value linked to the maximum competitiveness from an economic viewpoint, it is essential to have a lean organization characterized by efficiency in production processes. The organization must be able to rely on a well-established experience capable of managing any kind of order.

«With this approach – says Fabrizio Boeri – we face the market, carefully choosing the machines and processes which best fit to the type of product to be manufactured.»

In this regard, the market itself proves the company right, confirming high loyalty of acquired customers. And such customers operate in various sectors, from the demanding aeronautics to pneumatic sector, from modeling to the medical field, from food to automotive.

Production under control

Every single detail is totally manufactured within the company, ensuring maximum control over required products as a guarantee of total quality.

«Quality – says Fabrizio Boeri – is guaranteed by an operating process divided into several areas: the area dedicated to turnery operations, gearing department, grinding department, the area dedicated to metal processing, quality control department and logistics warehouse».

In particular, the turnery department hosts machinery, equipment and technologies allowing multiple processes, even the most complex ones, according to customers’ specific needs and internal management. Everything ensures maximum quality and precision. The main phase of the process is represented by the gearing department where the numerous machines are capable of preparing gears and microgears from module 0.25 to module 2.5, using synthetic and metallic materials in small and large sets for all types of processing.

«Production – says Fabrizio Boeri – is then directly managed and implemented in all its aspects, and only in this way we can ensure workpieces to have specific features and inherent characteristics of roughness, cleanliness, ecc., as more and more often it is strictly required by the market».

The above-mentioned properties are checked during the process and subsequently verified and certified in the control and quality department through profile projectors, roughness and hardness meters, as well as an accurate three-dimensional optical viewer combined with gear testers.

These operating assumptions allow the company to look to the future with great confidence, backed up by concrete means of growth and effective response to the market.

«A market – says Fabrizio Boeri – which records a steady increase in export share, now accounting by about 10% turnover, and which affects mainly the near Switzerland and Germany».

These are countries where, as it is well known, quality is not a secondary element but an essential requirement.